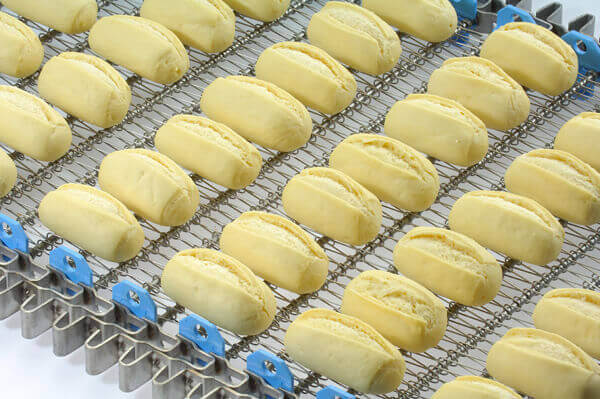

Preprocessing, cooling, and freezing of bakery products with IQF spiral freezer, IQF tunnel freezer, contact plate freezer, blast freezer or cold room, etc.

After the baking products are processed by the pretreatment equipment, they through the conveyor line to the IQF freezer or are put in a plate freezer for cooling or freezing.

According to the different pretreatment methods, the temperature of baking products entering the quick-freezing equipment will be different. The high-temperature products will be cooled with a spiral cooler or tunnel cooler before freezing, and then conveyed to the IQF freezer will save the cost.

According to the different freezing capacities, IQF spiral freezer is recommended for 200kg/h-4000kg/h, and the IQF tunnel freezer can be selected for 2000kg/h and below, impingement tunnel freezer with higher efficiency. Baking products will also use a spiral cooling tower, according to the actual area of the plant, combined with the characteristics of the tunnel freezer and spiral freezer, choose the appropriate IQF freezer, tunnel freezer is relatively long, and the spiral freezer is relatively high. If it is a new factory, before the construction, you can contact us, we have rich practical experience in food factories, can provide free technical support, and let you avoid waste of energy.

Baking products can also be packaged in pallets or other packages, placed in the freezing tray of the plate freezer, and frozen by the plate freezer. It is suitable for customers with small production and budget. According to the size and moisture content of the products, the general freezing capacity is 300kg/batch-1500kg/batch, about 3 hours for each batch. The plate freezer can also be made into multiple production lines frozen at the same time, which is widely used in some European countries extensively.

After the completion of freezing, through the automatic packaging production line, complete the packing, and finally sent it to the cold storage.

Global Office (Sales Consulting)

Email: info@elephantelf.com

Address: High tech Development Zone, Nantong City, Jiangsu Province, China

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

Address: No. 88, East Jindu Road, High-tech Industrial Development Zone, Nantong City, Jiangsu Province, China

We look forward to hearing from you!