Including:

Bread shrimp processing line, raw shrimp processing line with glazing machine, cooked shrimp processing line with glazing machine, quick frozen shrimp processing line, etc.

Brief Introduction:

Ice machine is a kind of refrigeration mechanical equipment that water is cooled by refrigerant of a refrigeration system through h evaporator to generate ice. According to the evaporator and the principle of the formation process, the shape of the ice is different. People generally divide the ice maker into particle ice machines, flake ice machines, plate ice machines, tube ice machines, shell ice machines, and so on.

Application Fields:

Aquatic products, food, supermarket, dairy, medicine, chemistry, vegetable preservation and transportation, marine fishing, and other industries.

Including:

Nuggets forming, coating, and battering line; meatloaf forming machine; coating powder machine; battering machine.

Including:

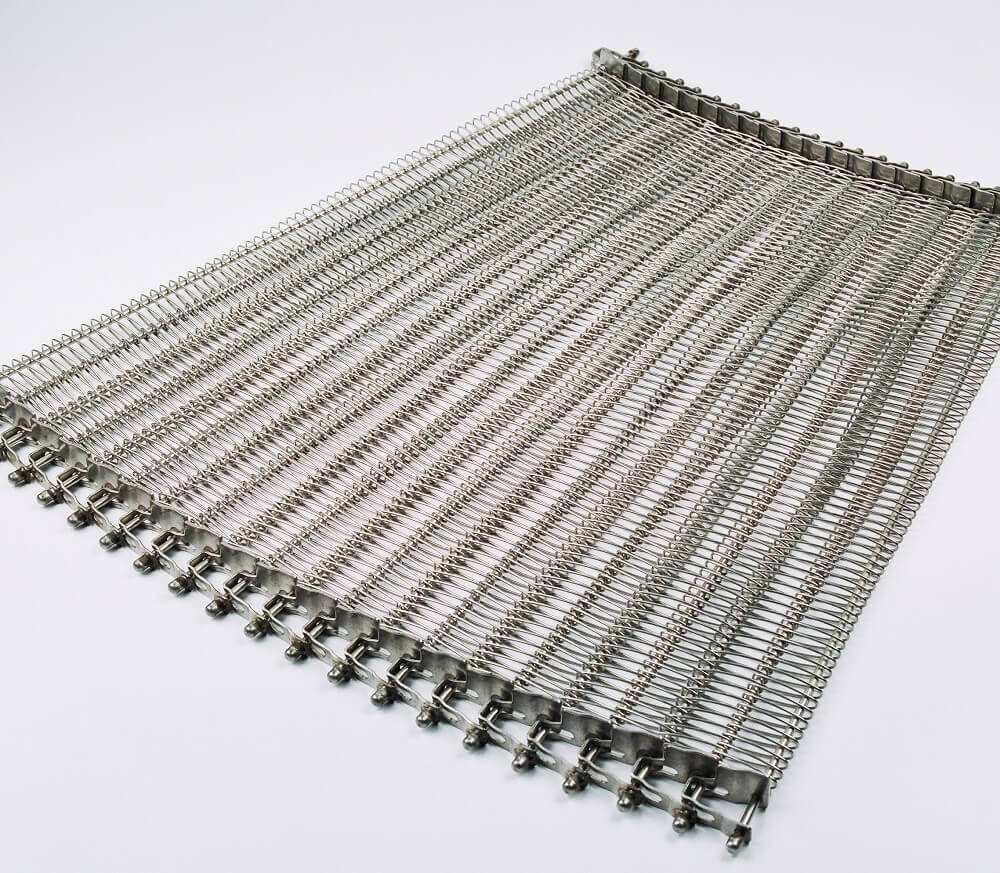

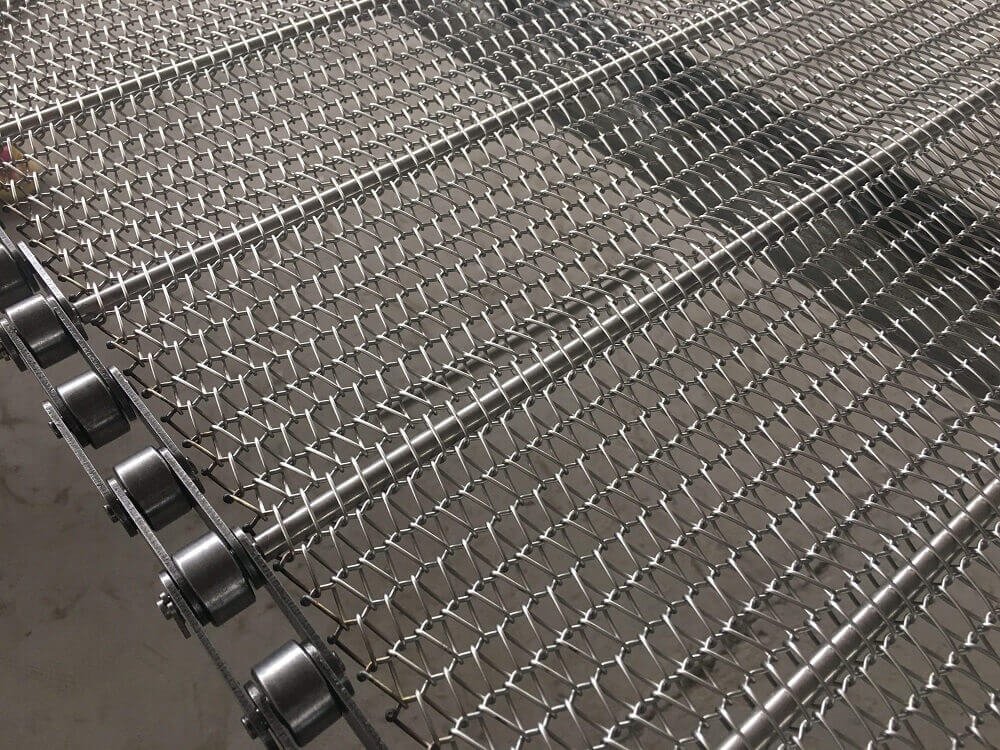

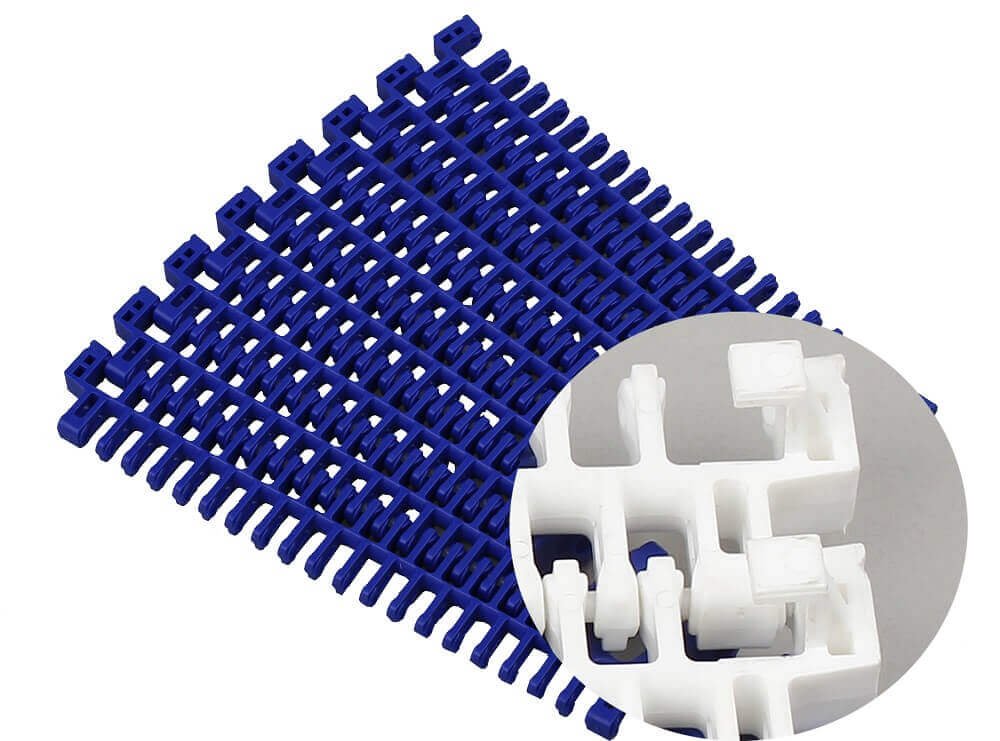

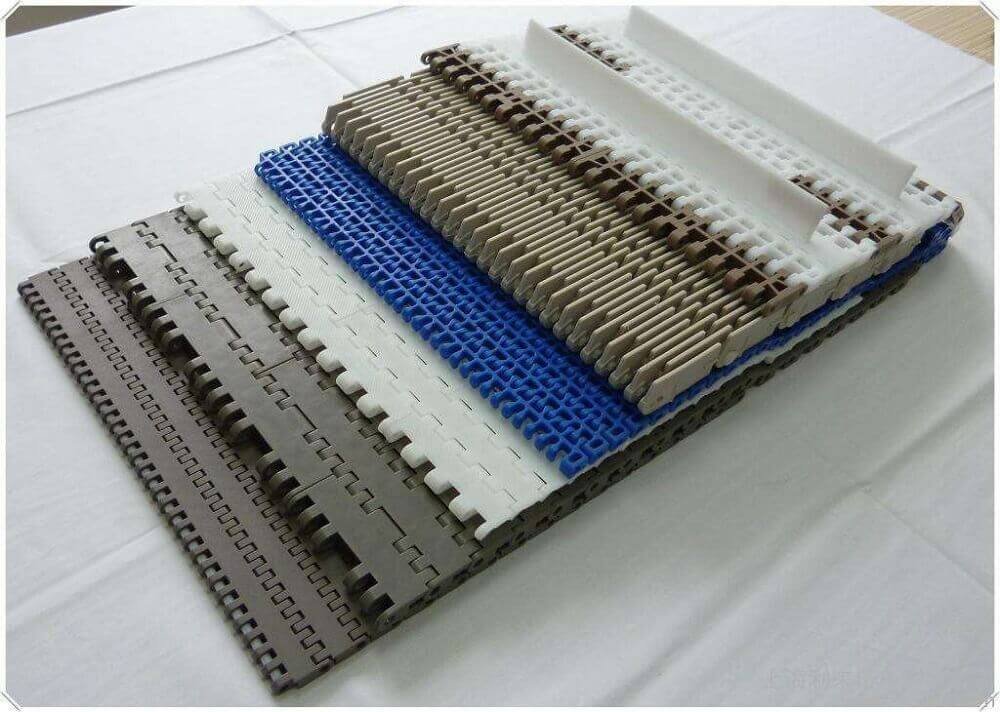

Stainless steel chain piece conveyor line, roller conveyor line, plastic mesh belt conveyor line and plastic linear mesh belt conveyor line, etc.

Including:

Screw mesh conveyor belt, herringbone mesh conveyor belt, zigzag mesh conveyor belt, plastic screw mesh conveyor belt, linear plastic mesh conveyor belt, etc.

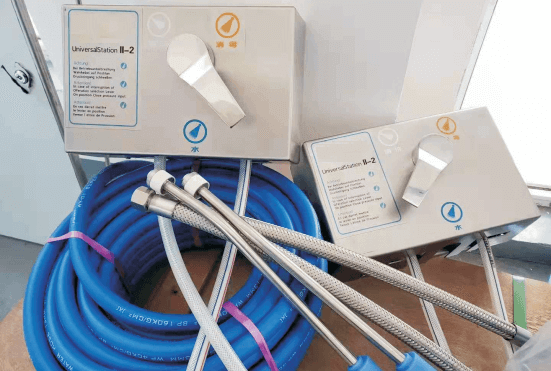

Basic Function:

Advantages:

·The cleaning time of each group of valves can be adjusted;

·The cleaning mode, cleaning steps, and cleaning area can be arbitrarily combined (programming mode).

·Stainless steel chemical tray, effectively prevents the corrosion of chemicals on the ground;

·Equipped with stainless steel level gauge, and empty barrel level alarm, to prevent invalid cleaning;

·The control system is equipped with an emergency stop button to shut down the system immediately in case of an emergency;

The foam master station has a flow sensor, and only when there is a water supply can the pump start;

·The operating system realizes the signal connection with the refrigeration equipment only when the chiller gives the cleaning signal。 The system can be activated to prevent the frothing system from being mistakenly activated during the production process.

·The system can automatically record the cleaning time, cleaning method, alarm, and display on the screen;

·The man-machine interface is friendly and the operation is convenient. With set password protection.

Any Comments From You Will Receive Our Prompt Reply In 12hrs.

Global Office (Sales Consulting)

Email: info@elephantelf.com

Address: High tech Development Zone, Nantong City, Jiangsu Province, China

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

Address: No. 88, East Jindu Road, High-tech Industrial Development Zone, Nantong City, Jiangsu Province, China

We look forward to hearing from you!