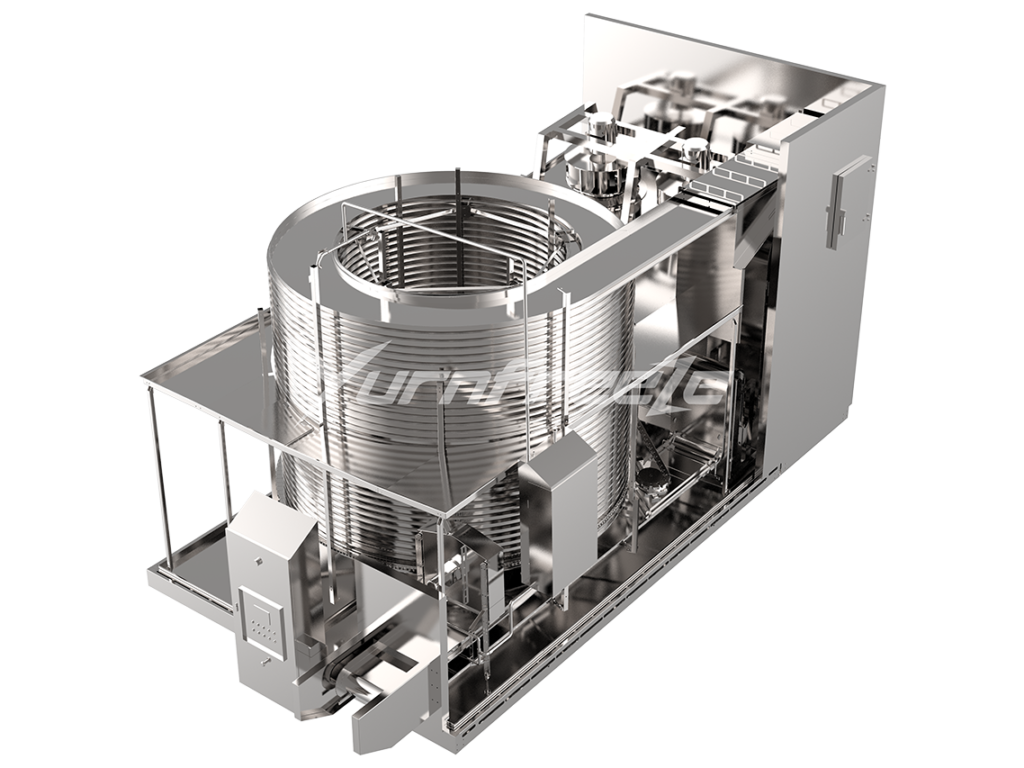

Self stacking Spiral Freezer

Quick-frozen prepared foods & FREEZING EOUIPMENT

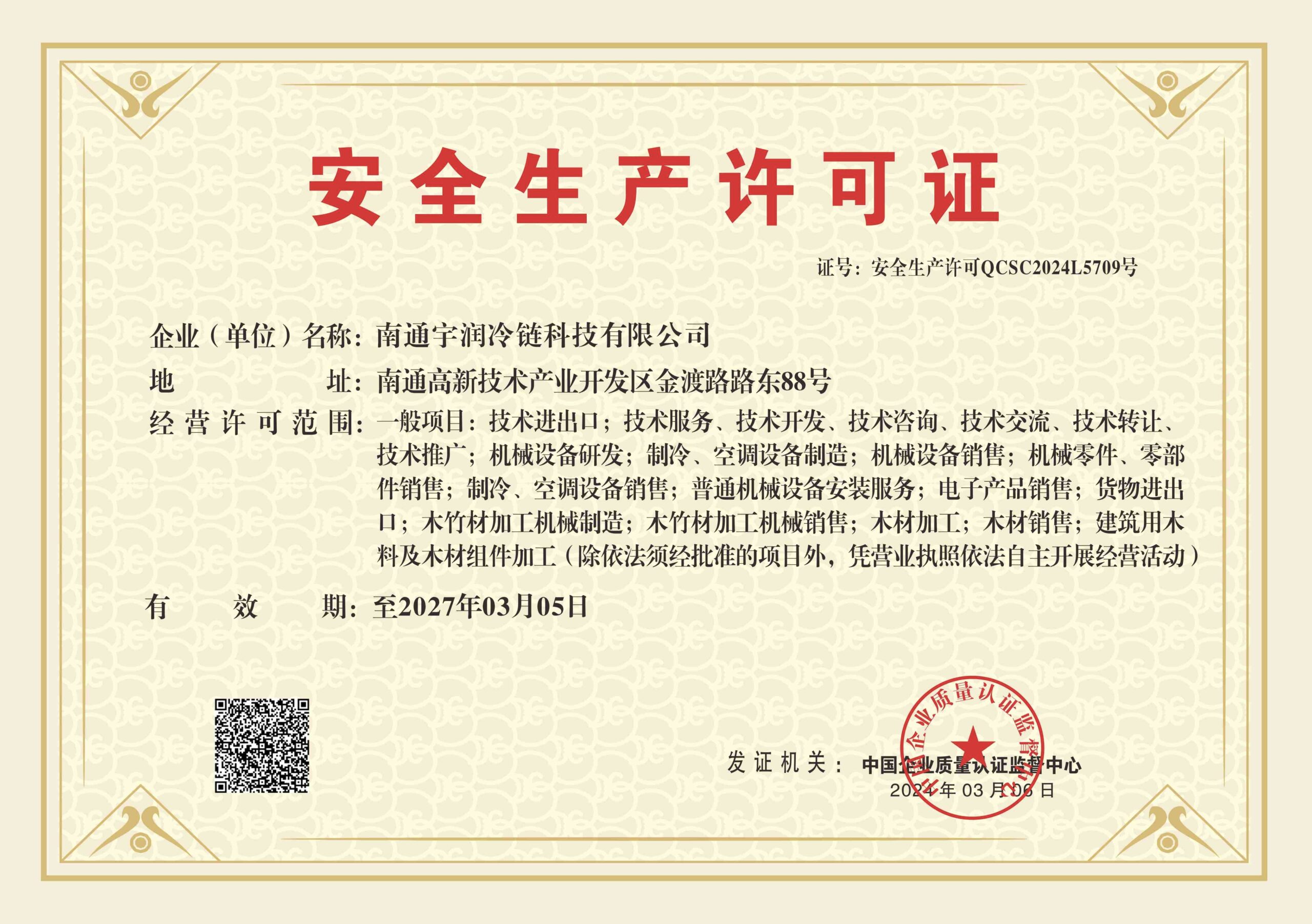

22 YEARS OF PRDUCTION EXPERIENCE

22 YEARS OF PRDUCTION EXPERIENCE

Efficiency

Our heat exchanger is precision-engineered for optimal performance:

Hydraulic tube expansion ensures tighter fin contact and better heat transfer

Variable fin pitch reduces frost buildup, extending operation time

Easy to clean with open-access design

Durable construction: Stainless steel/aluminum tubes with aluminum fins

Designed using advanced European thermal simulation software for reliable, energy-saving operation.

Our ADF system uses high-speed air pulses to remove frost from evaporator fins without stopping production, maintaining optimal heat transfer efficiency.

Benefits:

Continuous operation – No downtime for defrosting

150-200% longer runtime by preventing frost buildup

Energy efficient alternative to hot gas defrost

Ideal for spiral freezers and processing lines requiring uninterrupted operation.

Customized industrial refrigeration unit solutions

Multi-layer spiral freezing at -40°C maintains texture, with ice crystal diameter ≤50μm for premium cuts.

Continuous spiral processing preserves marine texture, handling 2-ton batches of whole fish/shrimp.

120-minute rapid freezing cycle maintains sauce integrity in marinated products, moisture loss <1.5%.

Precision temperature control at -34°C prevents fat separation in cheeses, maintaining 92% original texture.

35-minute spiral transit ensures dumplings/pastries maintain dough elasticity (rupture rate <0.8%).

Adjustable belt speed achieves 95% cell structure preservation for delicate berries and leafy greens.

Yihai Kerry (Fortune Global 500) is a global agri-food leader, producing edible oils, rice, and flour under brands like Golden Dragon Fish. Combining R&D innovation with sustainable practices, it delivers safe, efficient food solutions while advancing green manufacturing and rural development. A trusted partner for quality and industry impact.

Zhenjiang Chimei Chemical Co., Ltd. is a Taiwanese joint venture established in 1996 by Chimei Industrial Co., Ltd. of Taiwan, China. It is currently the largest plastic production base in mainland China. The company's annual production capacity totals 1.32 million tons and sales exceed 15 billion yuan.

Simcere Pharmaceutical Group is an innovation-driven biopharma with a National Key Laboratory. Focused on neuroscience, oncology, and immunology, it partners with global innovators to integrate R&D and collaboration, addressing unmet medical needs under its "living for patients" mission.

We look forward to hearing from you!