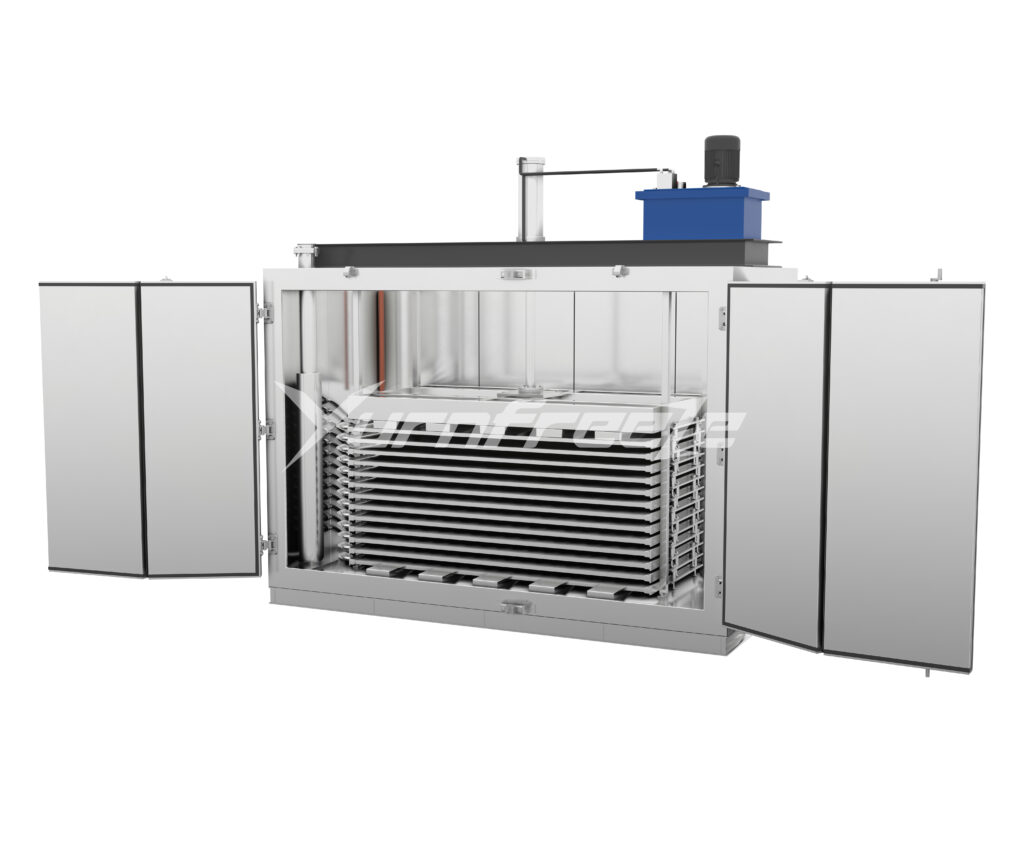

Plate Freezer

Plate freezer can quickly freeze products by moving up and down the inside aluminum plates. Products contact with two plates and realize heat exchange. Refrigeration system can be equipped as per different requirements of users.

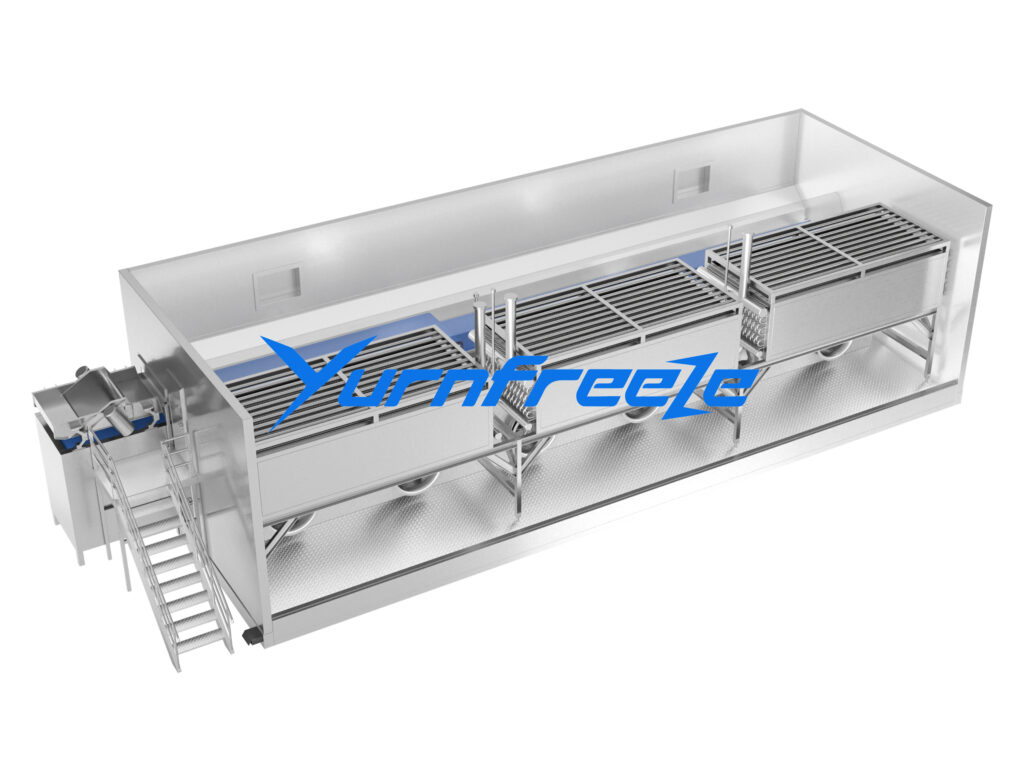

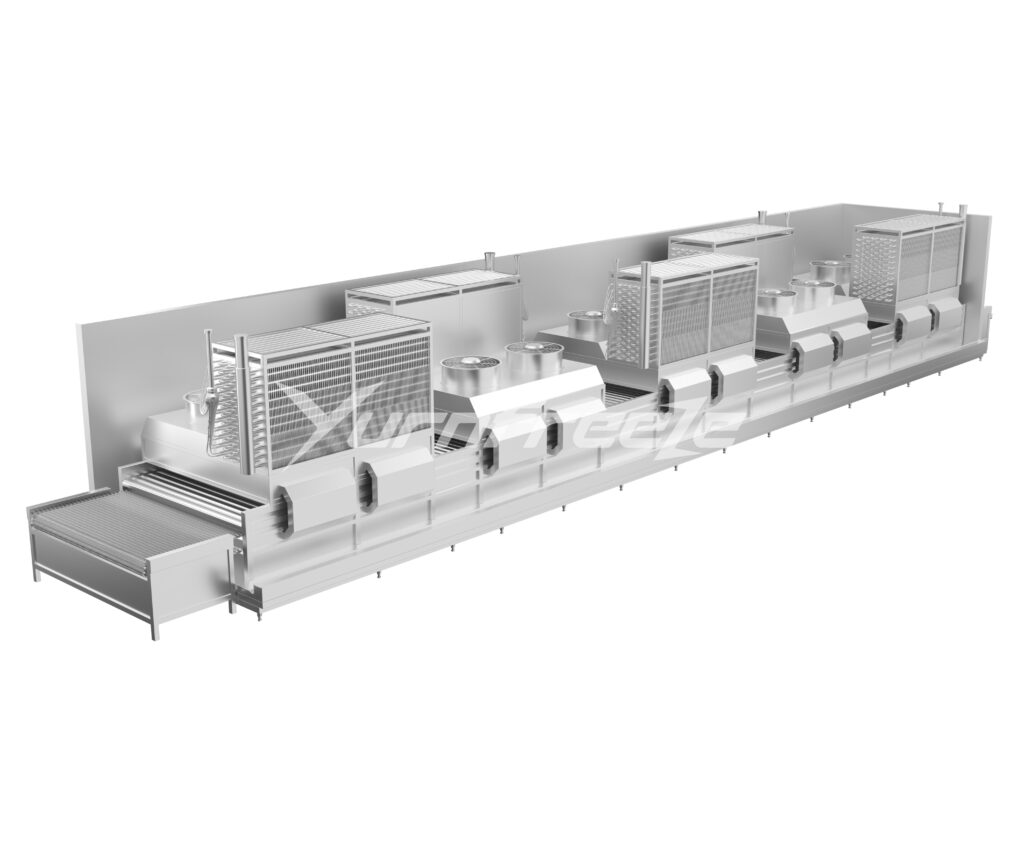

Blast Freezer

The main body of blast freezer is composed of thermal wall, roof, floor, door, bearing plate and base. It is good in thermal insulation and sealing. The refrigeration system of blast freezer insists of compressor, condensor, air cooler, etc. There are open type, semi-hermetic and fully hermetic compressors for customers’ option.

Related articles:

What is the difference between blast freezer and plate freezer?

How does a blast freezer work?

What is a plate freezer?