Ice build-up ruins freezing efficiency and wastes energy. Defrosting isn’t optional—it’s essential.

Industrial freezers use several defrosting methods like hot gas, electric, and water defrost. Choosing the right one helps keep freezing systems efficient, safe, and cost-effective.

[Table of contents]

Why Is Regular Defrosting Critical in Industrial Freezers?²

Defrosting is more than routine. It protects your freezer’s heart.

Without defrosting, frost builds up on evaporators. This lowers heat exchange efficiency and leads to more energy use, temperature spikes, and even product loss.

Frost build-up acts like a thermal blanket. It reduces airflow, causes temperature variation, and makes the refrigeration system work harder. When the coil surface is blocked by ice, the system runs longer to meet the set temperature. This raises your energy bill and shortens the life of compressors and fans.

Common Problems Caused by Inadequate Defrosting:

- Uneven Freezing:Ice blocks airflow, so some products freeze slower.

- Compressor Overload:Frosted coils force compressors to run longer.

- Product Spoilage:Ice buildup can cause sudden temperature swings.

- Safety Hazards:Excess frost can create slippery floors and ice falls.

From experience, the longer you delay defrosting, the more time and cost it takes to fix the damage. At YURNFREEZE, we help clients automate and optimize defrost cycles based on the size and usage of their freezing systems.

How Do Different Defrosting Methods Work in Industrial Freezers?

The most common industrial freezer defrosting methods include hot gas, electric heat, water spray, and off-cycle defrost. Each works in a unique way depending on the freezer type.

Hot Gas Defrost:This method reuses hot refrigerant gas from the compressor to heat up the evaporator coils¹. It’s fast and energy-efficient, especially in ammonia systems.

Electric Defrost:Electric heaters warm the coil surfaces. It’s precise but uses more energy. Good for small systems or areas where gas recovery isn’t practical.

Water Defrost:Water sprays melt frost quickly. This is effective but not suitable for all food-grade environments. It requires a proper drainage system.

Off-Cycle Defrost:The system simply stops cooling, and ambient air melts the frost. It’s energy-saving but works only when external temperature and humidity are low.

| Method | Energy Use | Speed | Maintenance | Best For |

| Hot Gas Defrost | Low | Fast | Medium | Large ammonia systems |

| Electric Defrost | High | Medium | Low | Small, precise applications |

| Water Defrost | Medium | Fast | High | Non-food-contact zones |

| Off-Cycle Defrost | Low | Slow | Low | Cold rooms, light load freezers |

How to Choose Different Defrosting Methods for Industrial Freezers and What Are the Criteria?³

To choose a defrost method, look at freezer type, food safety standards, energy cost, and environmental conditions.

Four questions help you choose:

- What kind of product are you freezing?

High-moisture items build frost faster. - How often does the freezer run?

Continuous systems need faster, more frequent defrost cycles. - What refrigerant are you using?

Ammonia systems pair well with hot gas defrost. - What’s the climate of your location?

High humidity areas need more efficient frost control.

For example, in Southeast Asia, we often install hot gas defrost in tunnel freezers. But in colder climates like Russia, off-cycle defrost sometimes works fine in cold storage rooms.Here’s a quick guide:

| Equipment Type | Best Defrost Method | Notes |

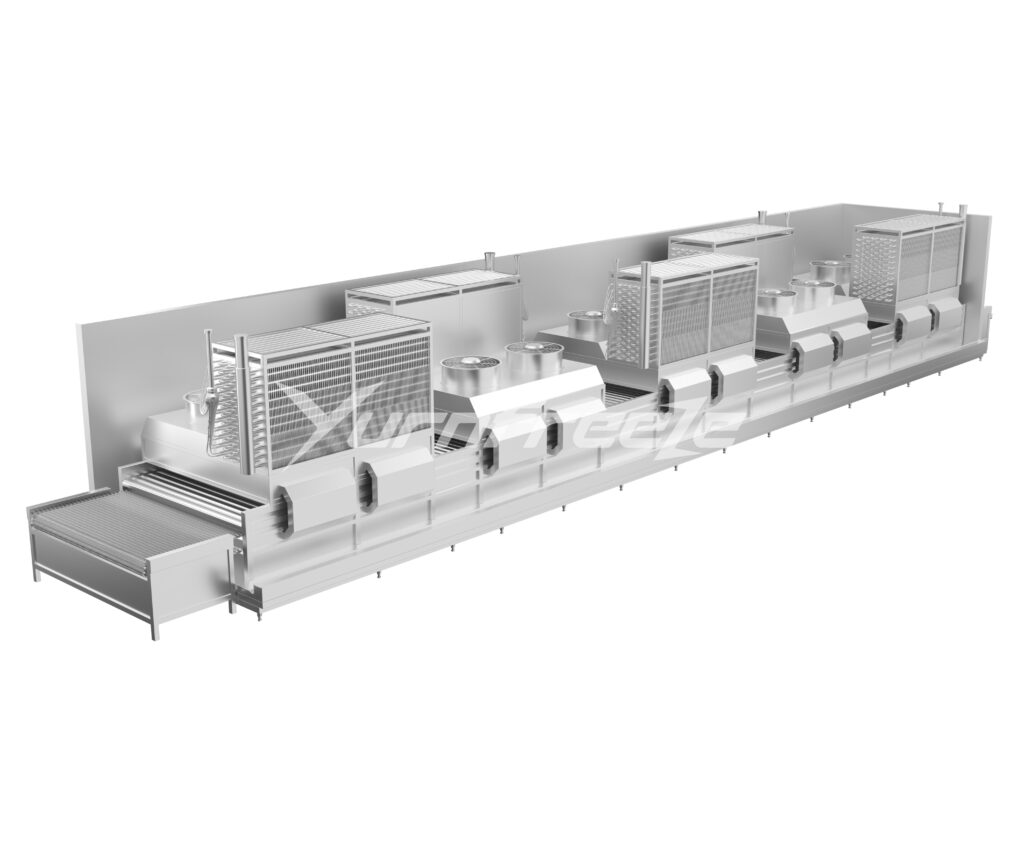

| Spiral Freezer | Hot Gas or Electric | For fast, continuous defrost |

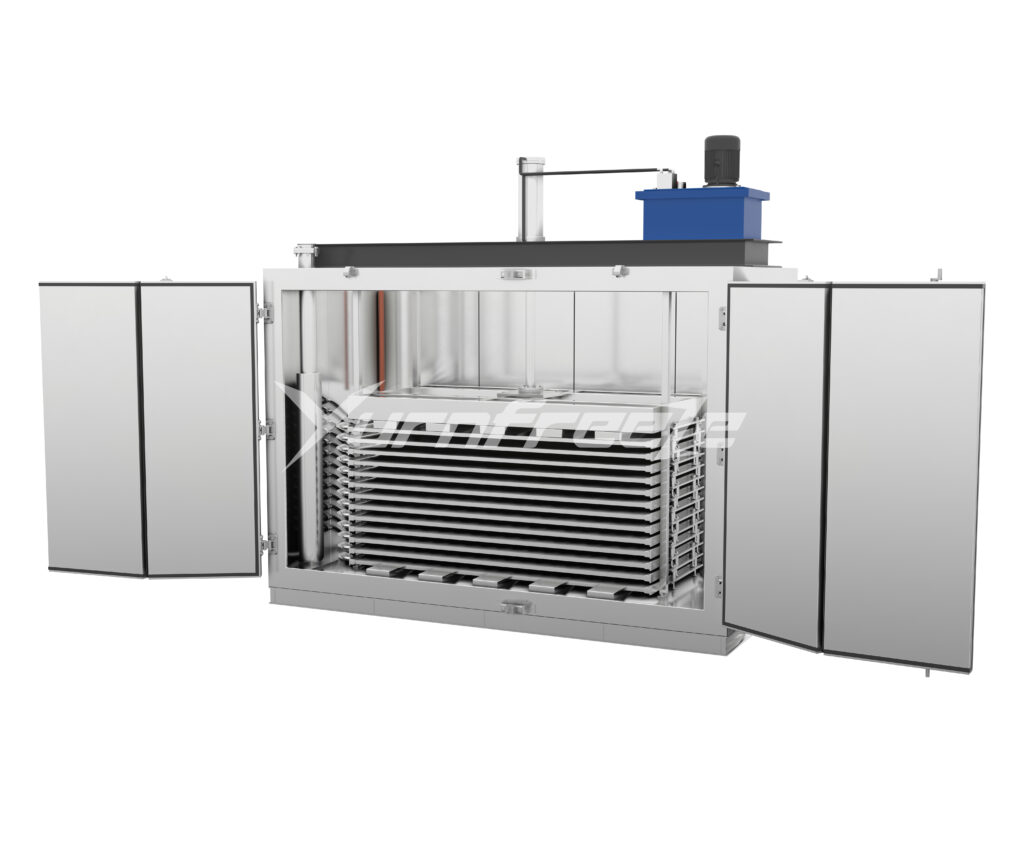

| Plate Freezer | Off-Cycle | Efficient with low-moisture loads |

| Fluidized Bed Freezer | Electric or Hot Gas | Must protect airflow integrity |

| Cold Room | Off-Cycle or Electric | Based on room temperature |

Join Yurnfreeze and Start Your Journey to Efficient Freezing

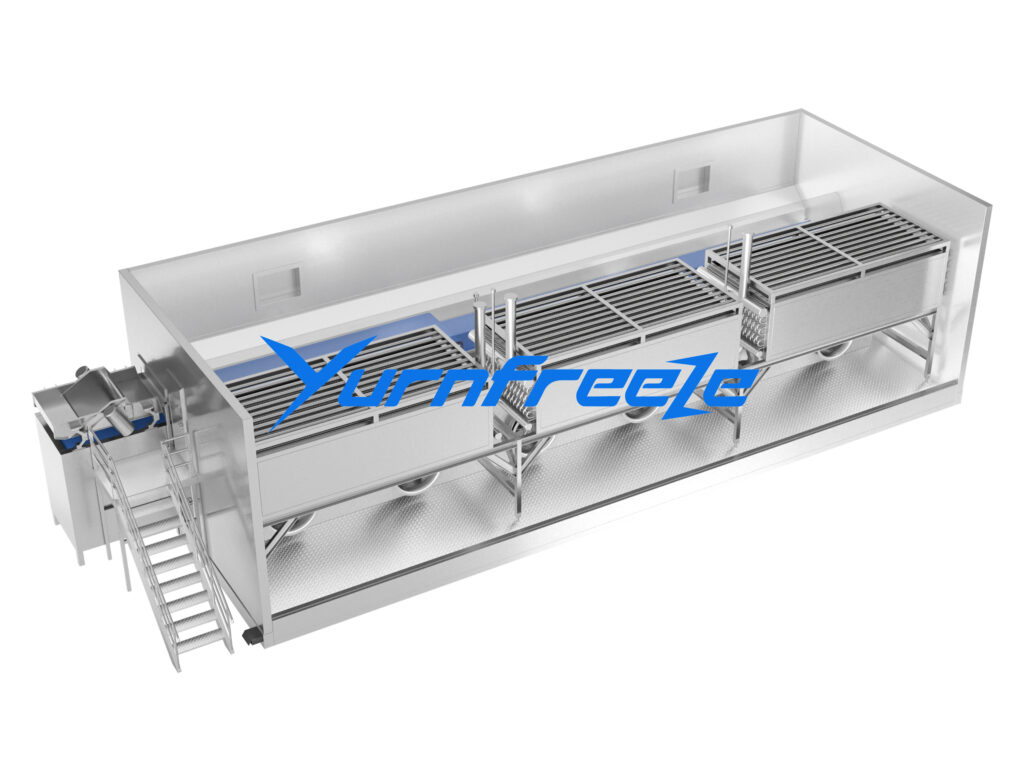

Yurnfreeze Tech Co., Ltd is more than just an equipment manufacturer—we’re your trusted partner in food processing. Our dedicated technical team is here to support you every step of the way, from solution design to after-sales service, ensuring your production line runs seamlessly. Visit our website at www.elephantelf.com to learn more about our self-stacking spiral freezers, or reach out to us at info@elephantelf.com to get a customized freezing solution tailored to your needs!

Conclusion

Right defrosting means better freezing and less waste.At YURNFREEZE, we often tailor defrost systems based on your region’s climate and your product’s moisture load.

Footnotes

- Explanation: Evaporator coils are critical for cooling performance. When ice covers the coils, it reduces efficiency and increases energy usage. The link explaining the science behind coil defrosting helps you understand why this process can’t be skipped.↩

- Explanation: Frost doesn’t just reduce efficiency—it raises operational costs and risks product spoilage. Click the link to a detailed explanation on effects of frost build-up on industrial refrigeration systems.↩

- Explanation: Different freezers need different defrost approaches. A breakdown of the best methods by freezer type helps operators make informed, system-specific decisions. Click here to learn the best defrosting method for your freezer.↩