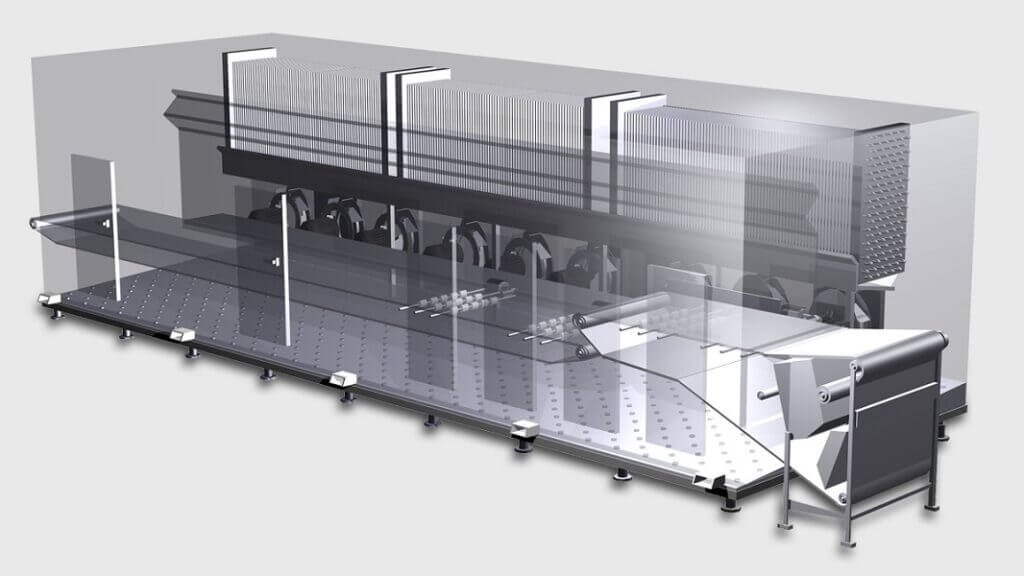

At this time, the fluidized bed body blows strong cold wind from bottom to top on the suspended food, and the frozen products receive cold wind flow in all directions to achieve rapid freezing of the food to form a single body, so that the frozen food quickly passes through the three stages of cooling, surface freezing, and deep freezing, thereby obtaining the highest quality quick-frozen food.

Capacity:

500kg/h~2000kg/h

Applicationa Area:

Vegetables, fruits, fungi, granular, sheet, block of quick-frozen food.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| FBF-500 | 500kg/h | +10℃/-18℃ | -38℃ | 8-40min adjustable | R717/R22 | 5000×4300×3300 |

| FBF-1000 | 1000kg/h | 7500×4300×3300 | ||||

| FBF-1500 | 1500kg/h | 11000×4300×3300 | ||||

| FBF-2000 | 2000kg/h | 14000×4300×3300 |

Note:

1. The freezing capacity refers to the haricot bean. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| FBF-500 | 500kg/h | +10℃/-18℃ | -38℃ | 8-40min adjustable | R717/R22 | 5000×4300×3300 |

| FBF-1000 | 1000kg/h | 7500×4300×3300 | ||||

| FBF-1500 | 1500kg/h | 11000×4300×3300 | ||||

| FBF-2000 | 2000kg/h | 14000×4300×3300 |

Note:

1. The freezing capacity refers to the haricot bean. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

A Fluidised IQF Tunnel Freezer stands out because it uses a stream of cold air to create a fluidized bed, which keeps each piece of product suspended during freezing. This prevents the items from clumping together, ensuring they freeze individually. Unlike traditional freezers that might freeze items in blocks or layers, this method is particularly useful for delicate products like berries, vegetables, and small seafood, as it preserves their shape and texture. The result is individually frozen pieces that are easy to package and use without defrosting everything at once.

Maintaining a Fluidised IQF Tunnel Freezer is essential for ensuring its efficiency and longevity. Key maintenance tasks include:

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

We look forward to hearing from you!