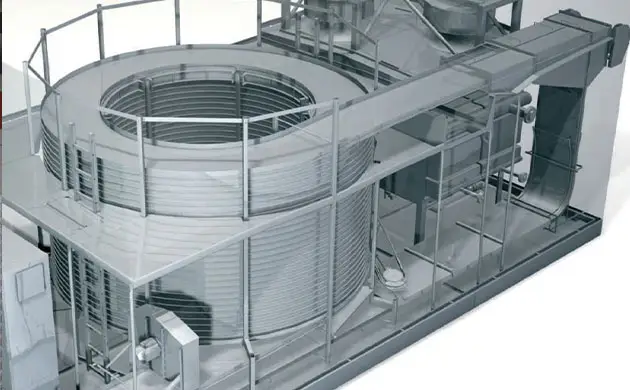

The self-stacking spiral freezing system uses an interlocking self-stacking conveyor belt that automatically stacks layer by layer on a sturdy chain-driven system. This design, combined with metal mesh wires and self-supporting side plates, creates a closed freezing zone that operates in continuous loops. By eliminating the need for belt rails and drums, it increases freezing capacity by 50% within the same footprint and is nearly 100% easy to clean. The controlled airflow circulates from top to bottom through the stacked zone, ensuring efficient heat exchange and reducing both freezing time and product moisture loss. Its compact and hygienic design makes it ideal for high-efficiency freezing needs.

Capacity:

200kg/h~3500kg/h

Applicationa Area:

It can quickly freeze most products suitable for conveyor belt transportation, especially small pieces of exposed products.

Compared to traditional freezing equipment, the self-stacking spiral freezer not only increases output within the same footprint but also meets higher hygiene standards and requires less maintenance. This makes it a perfect choice for food companies that prioritize sanitation, efficiency, and high-quality production.

Unlike traditional spiral freezing equipment, its self-stacking design eliminates the need for support rails and rollers, allowing the belt to stack directly on itself. This reduces the overall height and space requirements of the equipment.

This design minimizes equipment size while maintaining high freezing capacity, enabling up to 50% more production efficiency within the same space. It is particularly suitable for compact factories and production-intensive environments where efficient space utilization is critical.

Its compact structure not only optimizes factory layout but also reduces installation and maintenance complexities, enhancing ease of use.

The air defrost system in self-stacking spiral freezers is a highly efficient method designed to minimize downtime and maintain continuous operation. By using pressurized air blasts, this system removes frost buildup on evaporators, extending operational time and ensuring consistent freezer performance. This method also helps to reduce energy consumption and prevents excessive frost from impacting cooling efficiency, leading to shorter freezing cycles and better product quality.

The equipment can choose sequential defrost or steam injection fast defrost function, while some parts of the equipment are defrosted, other parts can continue to operate. This not only improves production efficiency, but also reduces water use compared to traditional systems, reduces costs and improves environmental protection.

The CIP (cleaning in place) system disinfects and cleans the evaporator, fan, spiral tower inside and outside, belt working surface and deck. The system is designed for repeated and consistent cleaning cycles, reducing the amount of water and detergent required for cleaning, while reducing labor costs.

Through automatic cycle cleaning, the CIP system ensures that the inside of the freezer maintains a high level of hygiene during production breaks, reduces the risk of contamination, and extends the time of continuous production operation.

Additionally, this setup optimizes sanitation and improves operational efficiency, helping to maintain product quality while minimizing waste buildup.

The self-stacking spiral freezer features a proprietary drive system that enhances its efficiency and performance.

This system minimizes energy consumption, reportedly saving up to 60% compared to traditional drum freezers. The unique design includes an optimized outfeed drive and a new automatic lubrication system, significantly reducing the power required for operation.

The PLC integrated control system in self-stacking spiral freezers provides precise management of all operational parameters. With multiple control modes available, users can adjust the settings to suit different freezing requirements, ensuring optimal performance and energy efficiency.

The integration of the PLC system also enables automated processes like defrosting and cleaning, minimizing manual intervention and reducing downtime.

This advanced control allows for real-time monitoring and adjustments, enhancing the overall reliability and efficiency of the freezing process.

A self-stack freezer and a traditional spiral freezer share similarities in using a spiral design for space efficiency and high freezing capacity. However, the main difference lies in the tray movement mechanism. Self-stack freezers do not have a fixed structure between the tiers; the trays themselves are stacked as they move, which improves airflow around each product and allows for better heat exchange. This results in more consistent freezing and potentially lower energy consumption. Traditional spiral freezers, on the other hand, have a fixed tier structure with a conveyor belt that moves products through a spiral path, making them more suited for certain types of production lines where consistent spacing is not as critical. Self-stack freezers are typically preferred when the goal is to maximize capacity within a limited space while maintaining even freezing.

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

We look forward to hearing from you!