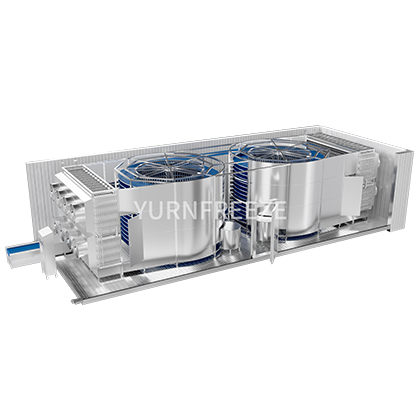

Spiral freezers have become essential equipment in the food processing industry, offering numerous advantages ranging from energy efficiency to superior food quality. These freezers are known for their ability to provide quick and uniform freezing, which is essential for maintaining the integrity of various food products while also boosting operational efficiency.

Advantages of Spiral Freezers

Efficiency and Cost-Effectiveness

Spiral freezers are designed to maximize energy savings by utilizing a continuous freezing process with a spiral conveyor system. The compact design enables a high throughput of food products with minimal space requirements, making it a cost-effective solution for large-scale food processing operations. The unique 360-degree freezing mechanism ensures that food is frozen evenly, reducing energy waste and enhancing the overall efficiency of the production line.

Consistent Quality and Reliability

One of the standout benefits of spiral freezers is their ability to freeze food products rapidly and uniformly. This rapid freezing process helps preserve the taste, texture, and moisture content of the food, ensuring that products maintain their high quality after freezing. Whether freezing meats, seafood, fruits, vegetables, or ready meals, spiral freezers provide consistent performance, helping producers maintain the desired quality of their products throughout the freezing process.

Hygienic Design and Safety Standards

Spiral freezers are engineered with hygiene and safety at the forefront. The design minimizes the buildup of ice, which can be a significant maintenance issue in other freezing methods. The closed freezing environment and controlled conveyor speed enhance food safety by reducing contamination risks and facilitating easier cleaning. This hygienic design ensures compliance with strict food safety standards, allowing for continuous and safe operation. Additionally, the ability to clean and sanitize these systems with minimal downtime contributes to higher overall safety and hygiene in food processing facilities.

Spiral freezers are suitable for all kinds of food

Spiral freezers are highly versatile and can handle a wide range of food types, making them an ideal solution for various sectors of the food industry.

Protein Products (Poultry, Meat, and Seafood):

Spiral freezing is particularly effective for preserving the moisture, texture, and flavor of protein-rich foods such as chicken, pork, and fish. This rapid freezing technique helps prevent bacterial growth, extending the shelf life of these products.

Fruits, Vegetables, and Ready Meals:

The spiral freezer is excellent for freezing fruits and vegetables, ensuring that they retain their nutritional value, color, and taste. This is crucial for individually quick frozen (IQF) products. Ready meals, such as lasagna and stir-fry, benefit from spiral freezing as it helps maintain the integrity and quality of mixed ingredients, ensuring the final product is ready for consumption with minimal loss in texture or flavor.

Bakery Products and Specialty Foods:

Spiral freezers are also ideal for delicate bakery items such as pastries and bread, which require precise and consistent freezing to preserve freshness and texture. For specialty foods like artisan cheeses and gourmet desserts, the spiral freezing process ensures that these premium products retain their unique qualities, making them a preferred choice for niche market producers.

In conclusion, spiral freezers are a key technology in modern food processing, offering efficiency, reliability, and versatility. Their ability to rapidly freeze a wide range of products while preserving quality and ensuring food safety makes them an indispensable tool for businesses in the food industry. Whether for mass production or specialty items, spiral freezers provide an optimal solution for efficient and high-quality freezing processes.