Freezing: The process of using the low temperature source generated by refrigeration to cool the product from room temperature and then freeze it.

Refrigeration: The process of using the cold effect generated by the change in the physical state of the refrigerant to obtain a low temperature source.

Types of refrigeration equipment: cold source production (refrigeration), freezing and cooling of materials.

Refrigeration methods: piston, screw, centrifugal refrigeration compressor units, absorption refrigeration units, steam jet refrigeration units and liquid nitrogen.

Freezing methods: air cooling, immersion and devices in which the refrigerant contacts the metal pipe, wall and material to transfer heat and cool down.

Refrigeration capacity: The amount of heat removed from the frozen material by the refrigerant per unit time under certain operating conditions (i.e., certain refrigerant evaporation temperature, condensation temperature, and supercooling temperature). It is also called the refrigeration capacity of the refrigerant. Under the same conditions, the refrigeration capacity of the same refrigerant is related to the size, speed and efficiency of the compressor.

Direct refrigeration: In the refrigeration cycle, if the evaporator where the refrigerant absorbs heat directly exchanges heat with the object to be cooled or the surrounding environment of the object to be cooled. It is generally used in single refrigeration equipment that requires industrial cooling, such as ice cream freezers, small cold storage and household refrigerators.

Refrigerant: The working substance that circulates continuously in the refrigeration device to achieve refrigeration. The vapor compression refrigeration device realizes heat transfer through the change of the physical state of the refrigerant. Refrigerant is an indispensable substance for realizing artificial refrigeration.

Indirect refrigeration: Use cheap substances as medium carriers to realize heat exchange between the refrigeration device and the cold-consuming place or machine.

Refrigerant: The cold generated in the evaporator of the refrigerant of the refrigeration device is transferred to the refrigeration device where the heat absorbed by the cooled object is transferred to the refrigerant, and then to the refrigerant, and it is used again for cooling and recycling.

Principle of indirect refrigeration: After the refrigerant absorbs cold from the refrigerant in the evaporator, it enters the cold storage through the brine pump, exchanges heat with the medium of the cooled object or the workplace to absorb heat, returns to the evaporator, and transfers the absorbed heat to the refrigerant, and it is used again for cooling and recycling.

Commonly used refrigerants: air, water, brine and organic aqueous solution.

Main devices of refrigeration equipment

Compression: used to compress the refrigerant to obtain energy, condense and expand to form a cold source that can absorb heat.

Condenser function: heat exchanger, which cools the superheated steam of the refrigerant to condense into liquid. There are horizontal shell and tube type, vertical shell and tube type, water spray type, evaporation type, and air cooling type.

Expansion valve function: reduce the pressure of the refrigerant and control the refrigerant flow. When the high-pressure liquid refrigerant passes through the expansion valve, the condensation pressure drops sharply to the evaporation pressure. At the same time, the liquid refrigerant boils and absorbs heat, and its own temperature decreases.

Evaporator function: the refrigerant absorbs the heat of the cooled medium and is divided into three categories according to the properties of the cooling medium.

- Evaporator for cooling liquid refrigerant;

- Evaporator for cooling air;

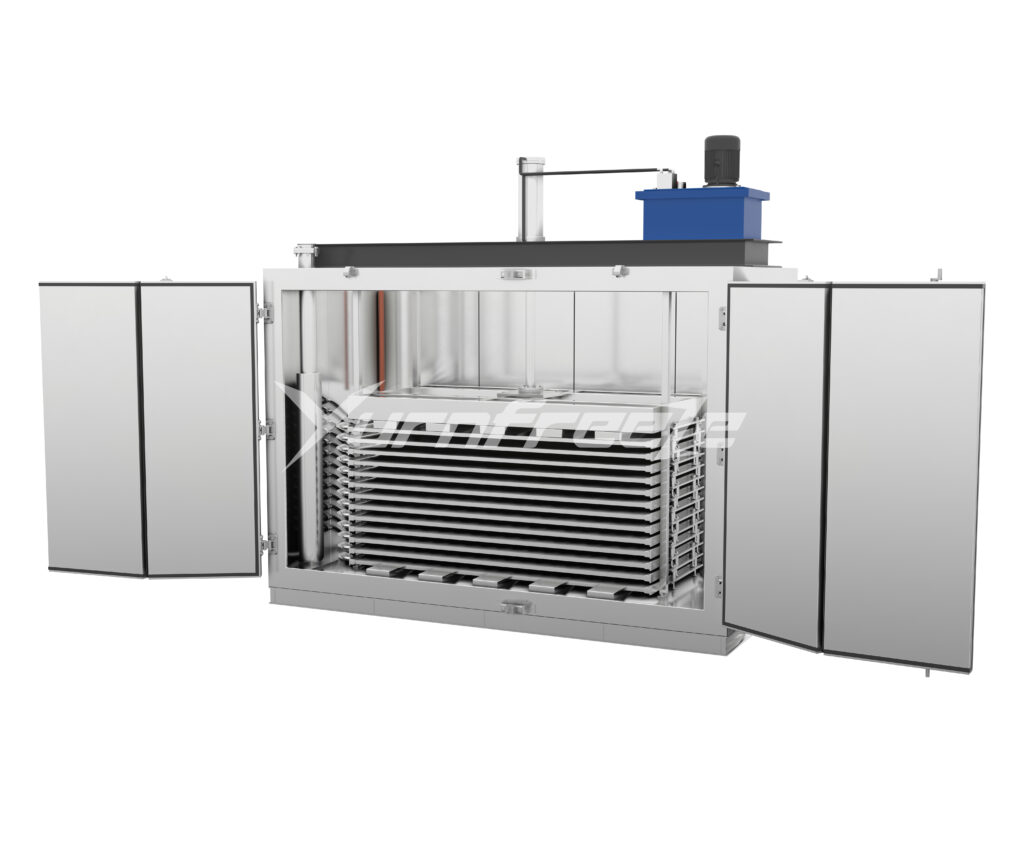

- Contact evaporator for cooling frozen materials;

Refrigeration cycle principle: When the refrigerant is in a low-temperature and low-pressure liquid state, it absorbs heat and reaches the boiling point, then evaporates to become low-temperature and low-pressure steam. The refrigerant evaporated into gas becomes high-temperature and high-pressure gas under the action of the compressor. This high-temperature and high-pressure gas condenses into high-pressure liquid. The high-pressure liquid passes through the expansion valve and becomes a low-pressure and low-temperature liquid. It absorbs heat and evaporates again, forming the refrigeration cycle of the refrigerator.

Vertical cooling pipe: refrigerant is easy to discharge after vaporization, and the heat transfer effect is better, but when the pipe is high, the evaporation temperature of the lower refrigerant is higher due to the static pressure of the liquid column.

Single-row coil wall pipe: the amount of refrigerant is small, about 50% of the pipe volume, but the refrigerant will not be quickly discharged from the pipe after vaporization, which reduces the heat transfer effect.

Warp-fin pipe: large heat dissipation area.

Oil separator function: used to separate the lubricating oil carried in the compressed liquid gas to prevent the lubricating oil from entering the condenser and deteriorating the heat transfer conditions.

Oil collector function: collect the refrigerant and oil mixture separated from the oil separator, condenser and other devices of the refrigeration system, and then separate the oil from the mixed refrigerant under low pressure, and then release them separately, so as to ensure the safety of oil discharge and reduce the loss of refrigerant.

Liquid storage function: store and adjust the liquid refrigerant supplied to various parts of the refrigeration system to meet the safe operation of the equipment. The liquid storage tank is divided into high pressure, low pressure, discharge tank and circulating liquid storage tank.

Function of gas-liquid separator: Separate the refrigerant from the evaporator to prevent the refrigerant liquid from entering the compressor and causing knocking; Separate the ineffective steam in the low-pressure ammonia liquid after throttling to improve the heat transfer effect of the evaporator.

Function of air separator: Separate the non-condensable gas in the exhaust system to ensure the normal operation of the refrigeration system.

Function of intercooler: Installed in a two-stage (or multi-stage) compression refrigeration system, it is used to cool the superheated gas discharged from the low-pressure stage for inter-stage cooling to ensure the normal operation of the high-pressure stage compressor; Separate the lubricating oil carried in the low-pressure exhaust gas, and cool the refrigerant to obtain a larger degree of supercooling.