At present, in addition to traditional mechanical refrigeration methods, more efficient liquid nitrogen ultra-low temperature freezing technology has also been widely used. Pre-prepared food and seafood processing companies can choose the appropriate freezing process based on their own comprehensive considerations of product quality, production capacity configuration, management efficiency and financial returns.

Product Quality

Whether in the process of food freezing (evaporative product net weight loss) or food thawing (juice loss), all freezing processes will cause different degrees of water loss in food. Especially for aquatic products, evaporative net weight loss reduces the net content of the product and its added value. At the same time, the dry loss on the surface of the food affects the taste, texture, color and cooking time of the product. For example, the fish body contains 70~80% water. When the temperature drops to 0~-5℃, most of the water in the fish body freezes to form larger ice crystals, which is called the maximum ice crystal formation temperature zone. The faster the freezing speed, the shorter the time to pass through the maximum ice crystal formation zone, and the better the quality of the frozen product. Therefore, the quality of fish products is closely related to the freezing speed. The extremely fast freezing speed of liquid nitrogen can make the water in the cells and the intercellular space freeze into countless fine and uniform ice crystals almost at the same time, so that the cell tissue is not damaged, so that the food can be restored to its original fresh state and original nutrients to the maximum extent after thawing.

Capacity Configuration

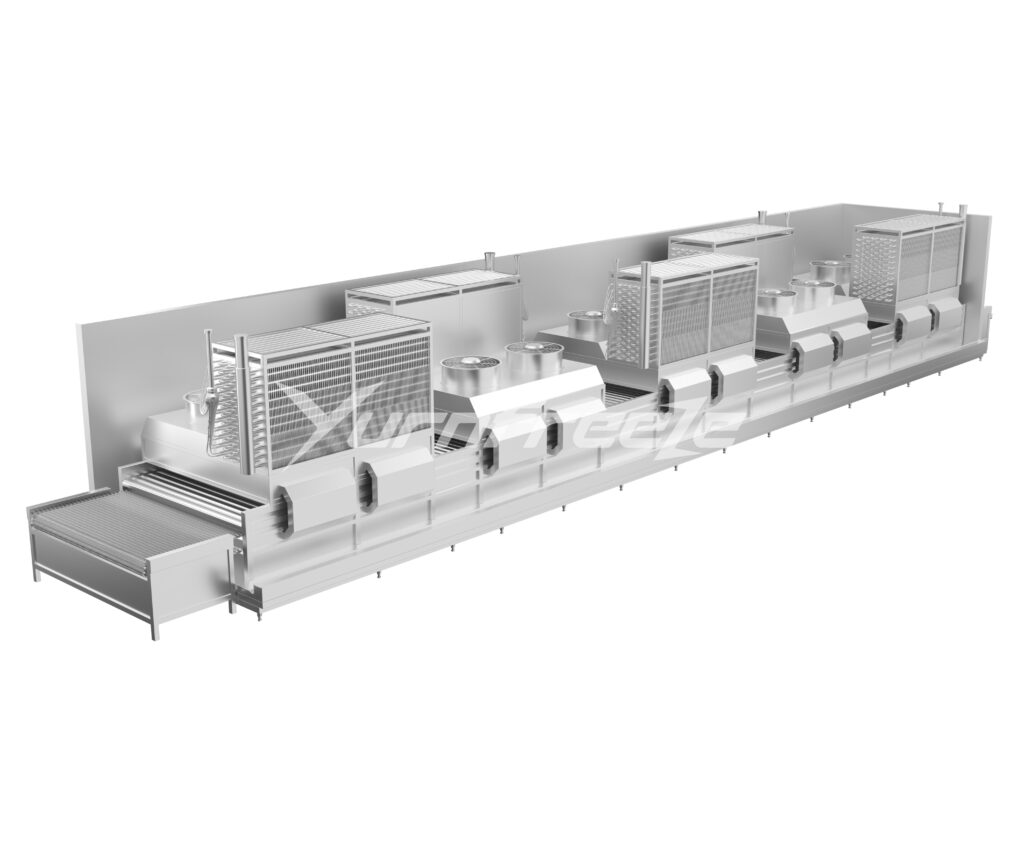

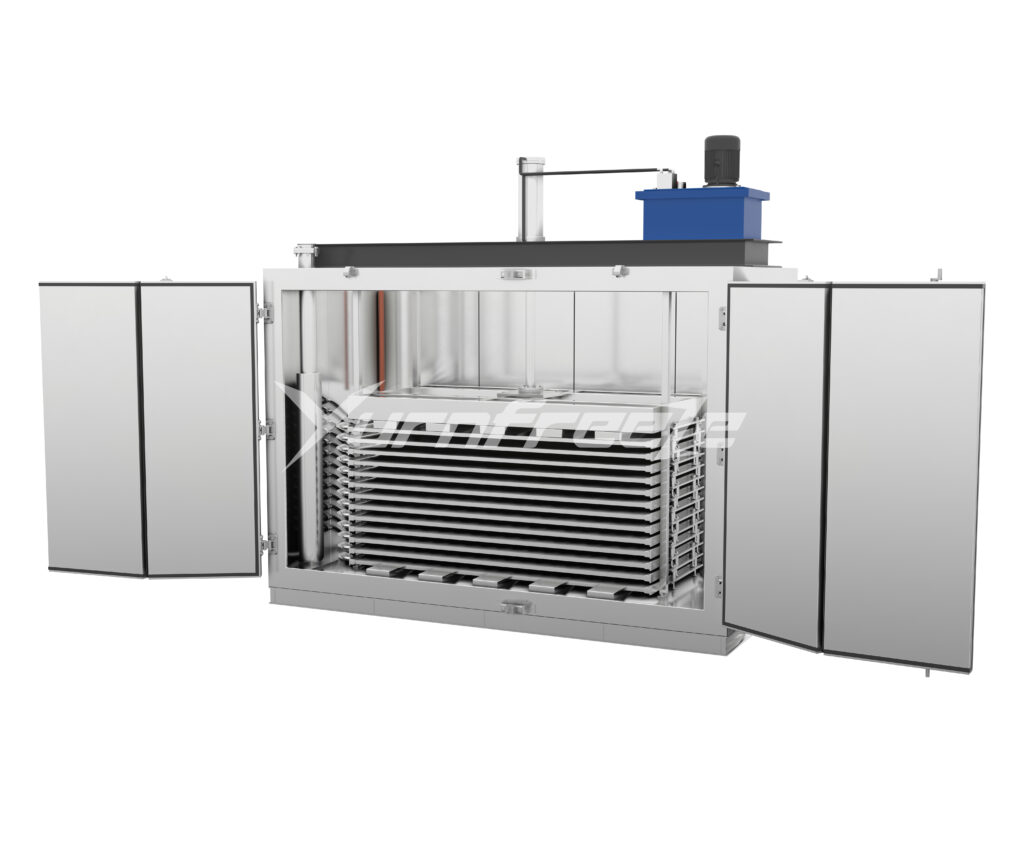

For mechanical refrigeration equipment, the payback period can last several years. Overly optimistic forecasts will result in reduced efficiency, while conversely, pessimistic plans will result in insufficient food freezing capacity. Mechanical food freezing equipment has a fixed maximum capacity for any specific product, but ultra-low temperature food freezing equipment can be quickly adjusted by increasing the length of the tunnel to adapt to changes in production capacity. Importantly, ultra-low temperature food freezing equipment can be leased, and changes in production capacity requirements do not require food processing companies to significantly increase additional capital investment.

Factory Management

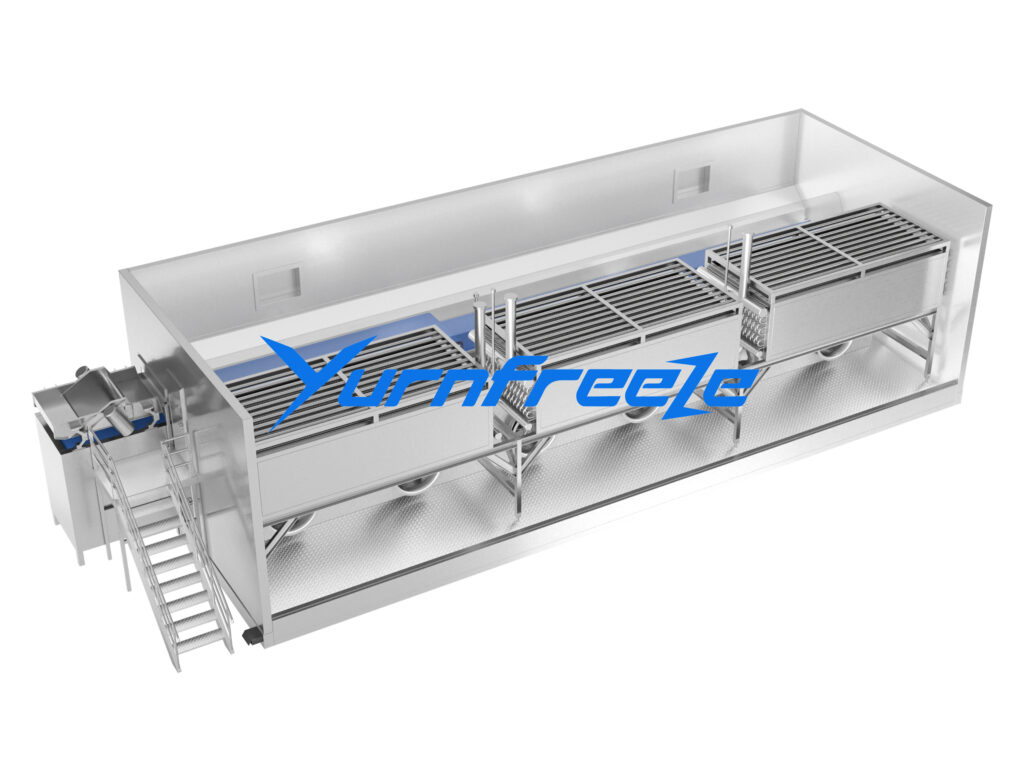

In almost all cases, ultra-low temperature food freezing takes up less space than traditional mechanical freezing at the same production capacity. When the production capacity is 500 kg/hour, the former only needs 6.4 square meters, while the latter needs 19.5 square meters. The smaller size and simple internal structure of the device also facilitate the daily maintenance and operation of the operator.

Financial Returns

There is a clear difference in the cost of ultra-low temperature food freezing and mechanical freezing equipment. The former has higher operating costs, while the latter requires a large initial capital investment. However, there is a critical point for any given production line, at which the cumulative operating costs of the ultra-low temperature freezing process will exceed those of the mechanical refrigeration process.

However, compared with the 3-6% dry loss rate of traditional freezing, the dry loss rate of liquid nitrogen quick freezing can be reduced to 0.25-0.5%. Considering the cost savings brought by the loss of high-value products and the business opportunities brought by improved product quality, ultra-low temperature food freezing will bring more long-term economic returns.

The use of liquid nitrogen to quick-freeze food first began in the United States. The United States began research in this area in the 1950s, and it was officially used for quick-frozen food in 1960. In 1965, Air Products, as a global leading one-stop solution provider of gases, equipment, and services, took the lead in helping food processing companies in the United States use liquid nitrogen for quick freezing of food. Since then, the company has begun to provide high-quality gases and advanced equipment technologies for various processing applications to customers in the food industry. Today, Air Products’ Freshline liquid nitrogen solutions are widely used in the freezing, cooling and modified atmosphere packaging of foods such as seafood, meat and poultry, prepared dishes, baked goods, fruits and vegetables.