Shelf plate freezers, or air blast freezers, are highly efficient freezing solutions designed to maximize space utilization and accelerate freezing.

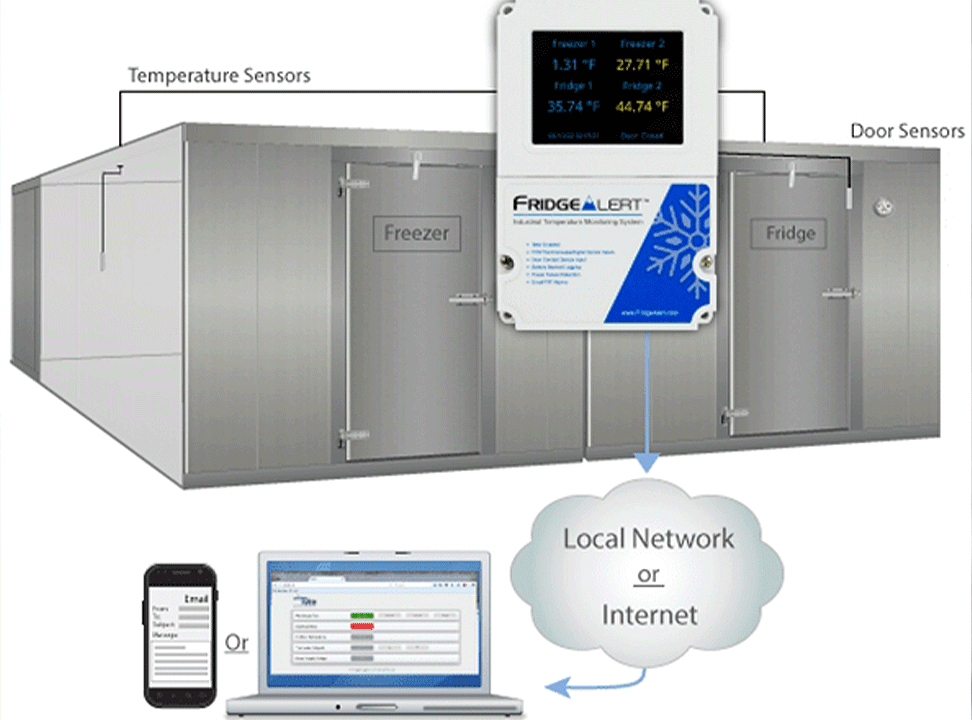

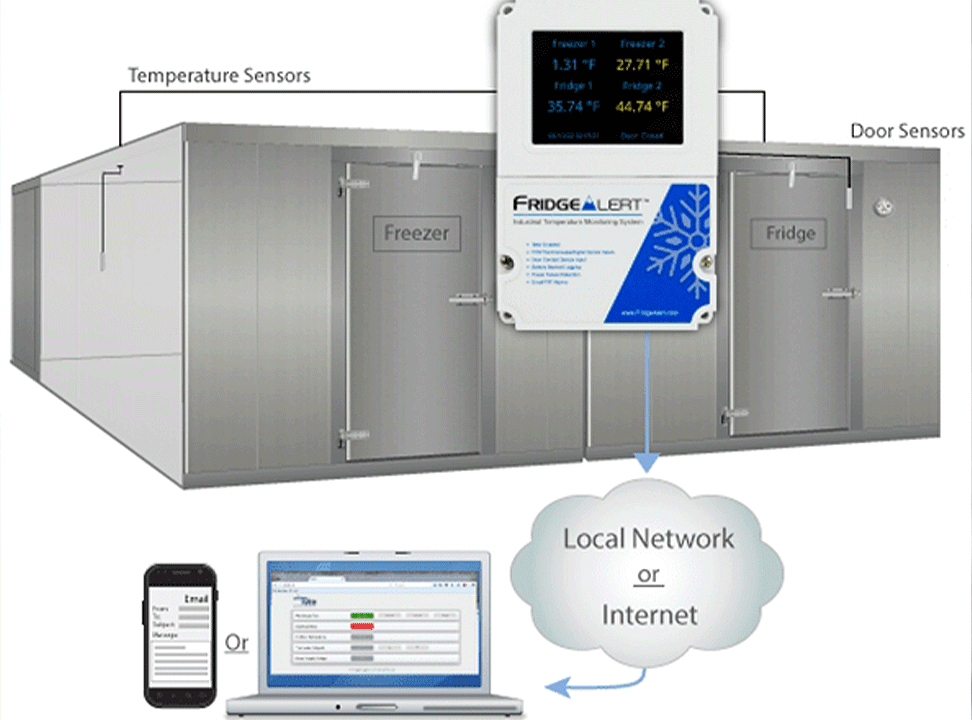

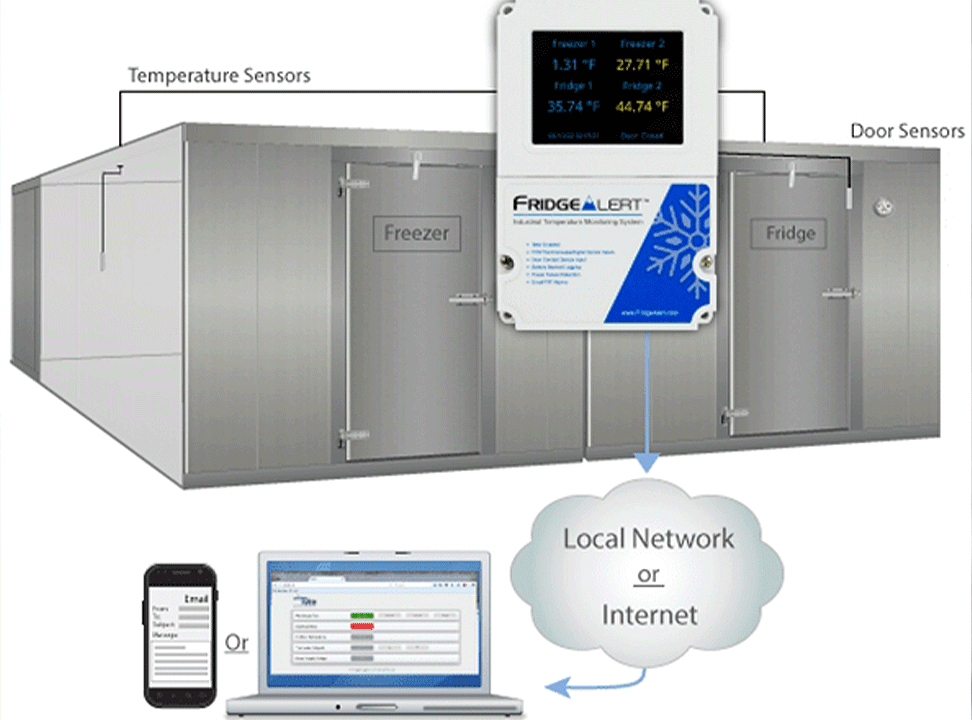

This Air Blast Freezer uses advanced technology to deliver rapid and even cooling, ideal for industries that require consistent temperature control. Unlike traditional freezers, it is often combined with an air-blast freezer system, enhancing the freezing process by circulating cold air evenly throughout the air-blast freezer room. This ensures optimal product quality retention, making it suitable for seafood, meat, and other frozen goods. Its compact design allows for easy integration into various industrial setups.

Applicationa Area:

It is used in processing frozen fish fillets, surimi, shrimp, shellfish, and other aquatic products and meat small packaging, and other food on fishing boats.

| Model | Freezing Capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| PGA-1000 | 1100 | +15℃/-18℃ | -35℃ | 120-240min adjustable | R717/R22/404a | 3300×1900×2100 |

| PGA-1500 | 1540 | 5800×1900×2400 | ||||

| PGA-3000 | 3080 | 8500×1900×2400 | ||||

| PGA-5000 | 4620 | 8500×1900×3100 |

| Model | Freezing Capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| PGA-1000 | 1100 | +15℃/-18℃ | -35℃ | 120-240min adjustable | R717/R22/404a | 3300×1900×2100 |

| PGA-1500 | 1540 | 5800×1900×2400 | ||||

| PGA-3000 | 3080 | 8500×1900×2400 | ||||

| PGA-5000 | 4620 | 8500×1900×3100 |

The shelf-type quick freezer is often referred to as an airflow quick freezer because it uses powerful fans to circulate cold air throughout the freezing chamber. This airflow ensures even distribution of low temperatures across all shelves, leading to faster and more uniform freezing of products placed on the shelves. The consistent air movement reduces temperature variations and allows for a more efficient freezing process compared to static cooling methods. This design makes it suitable for freezing products like packaged food items or trays of seafood that require quick and even freezing.

The working principle of an air blast freezer involves using high-velocity cold air to rapidly reduce the temperature of products. Here’s how it works:

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

We look forward to hearing from you!