The double-drum spiral freezer is a new series of high-efficiency freezing equipment developed based on the single-drum spiral freezer. It achieves fast and uniform freezing through two drums that operate in a left-right spiral structure. Compared to the single-drum spiral freezer, the double-drum spiral freezer significantly increases the freezing capacity with only a slight increase in volume, highlighting its compact structure and small footprint. Additionally, the equipment can be customized in design and manufacturing according to customer requirements and space constraints.

Capacity:

500kg/h~3000kg/h

Applicationa Area:

Suitable for foods with a short freezing time such as pasta, vegetables, shrimps, meat skewers, etc. Also suitable for freezing large pieces of food such as cut meat, ice cream, fish, etc.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| DSF-500 | 500kg/h | +25℃/-18℃ | -35℃ | 15-75min adjustable | R717/R22 | 10800×4300×3000 |

| DSF-750 | 750kg/h | 11200×4700×3000 | ||||

| DSF-1000 | 1000kg/h | 20-100min adjustable | 12800×5300×3000 | |||

| DSF-1500 | 1500kg/h | 12800×5300×4000 | ||||

| DSF-2000 | 2000kg/h | 14000×6000×4000 | ||||

| DSF-2500 | 2500kg/h | 14600×6000×3920 | ||||

| DSF-3000 | 3000kg/h | 14600×6000×4220 |

Note:

1. The freezing capacity refers to fried chicken. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| DSF-500 | 500kg/h | +25℃/-18℃ | -35℃ | 15-75min adjustable | R717/R22 | 10800×4300×3000 |

| DSF-750 | 750kg/h | 11200×4700×3000 | ||||

| DSF-1000 | 1000kg/h | 20-100min adjustable | 12800×5300×3000 | |||

| DSF-1500 | 1500kg/h | 12800×5300×4000 | ||||

| DSF-2000 | 2000kg/h | 14000×6000×4000 | ||||

| DSF-2500 | 2500kg/h | 14600×6000×3920 | ||||

| DSF-3000 | 3000kg/h | 14600×6000×4220 |

Note:

1. The freezing capacity refers to fried chicken. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

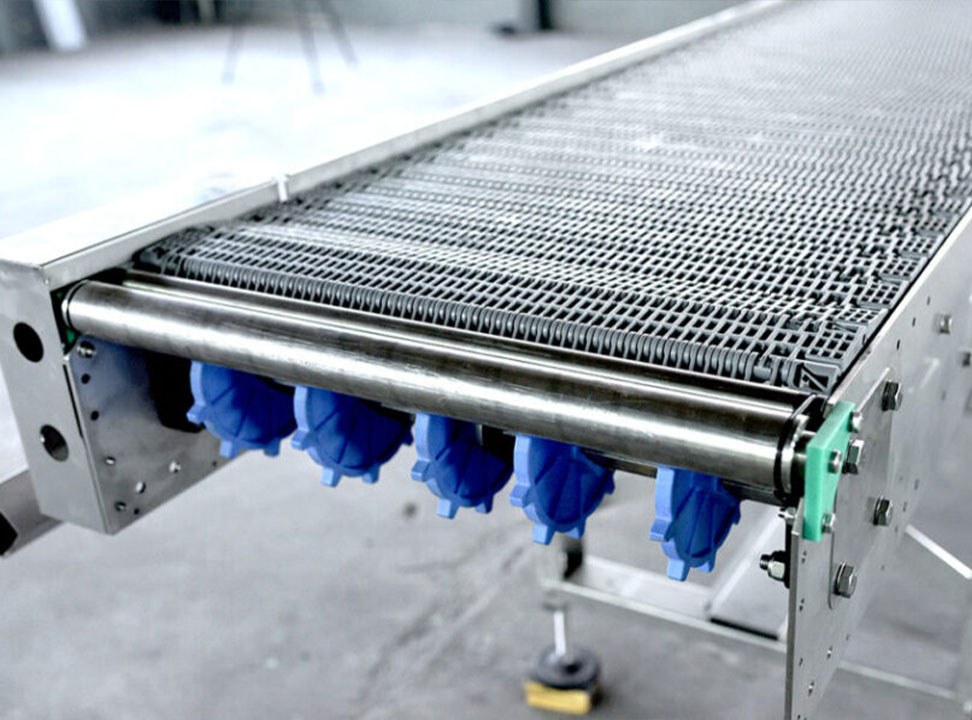

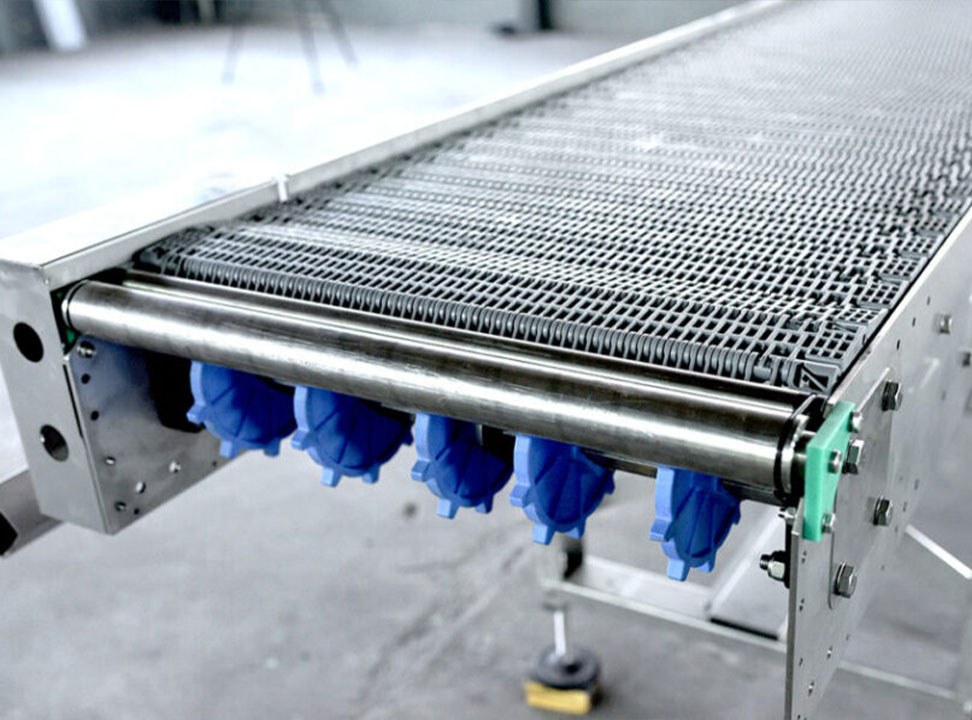

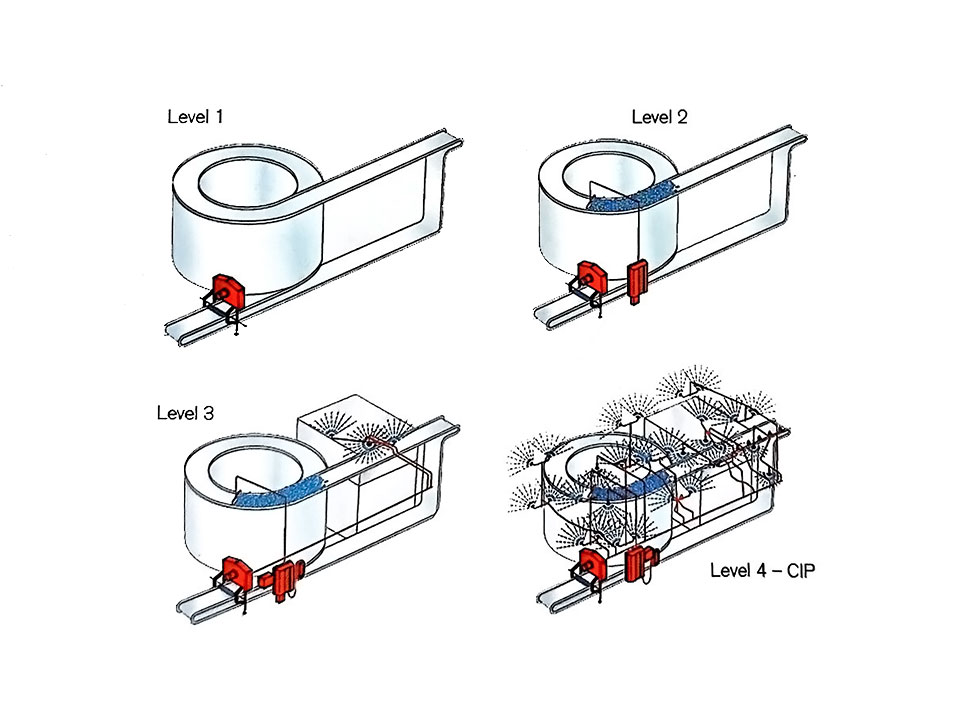

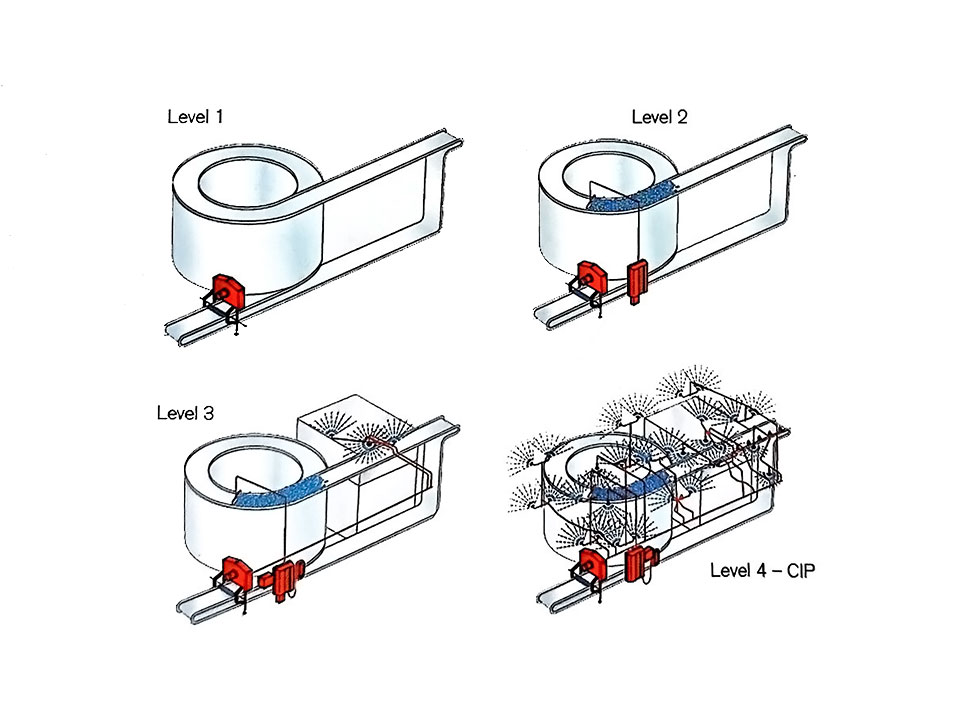

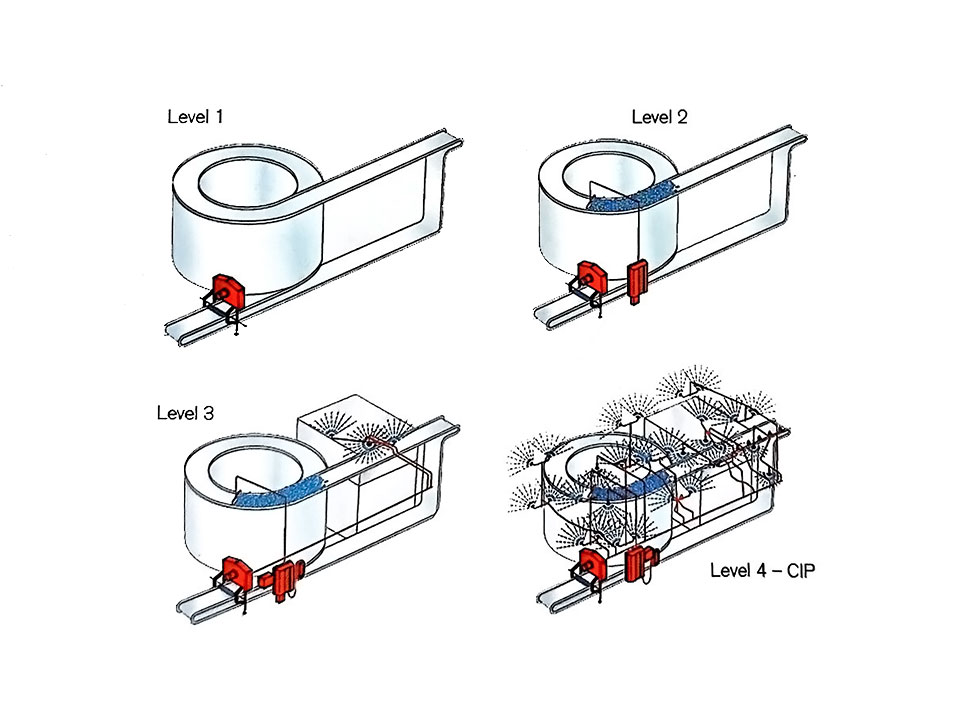

A spiral freezer is an industrial freezer designed to efficiently freeze large quantities of food in a compact space. Using a spiral conveyor system, it ensures fast, even freezing, making it ideal for seafood, poultry, baked goods, and ready meals. Key benefits include space efficiency, consistent freezing, and hygienic design, meeting high-volume production needs while preserving product quality.

A spiral freezer works by using a spiral conveyor belt to move products through a freezing chamber. Cold air circulates evenly around the products, ensuring rapid and uniform freezing. Its compact design maximizes freezing capacity while maintaining energy efficiency, making it ideal for high-volume food processing.

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

We look forward to hearing from you!