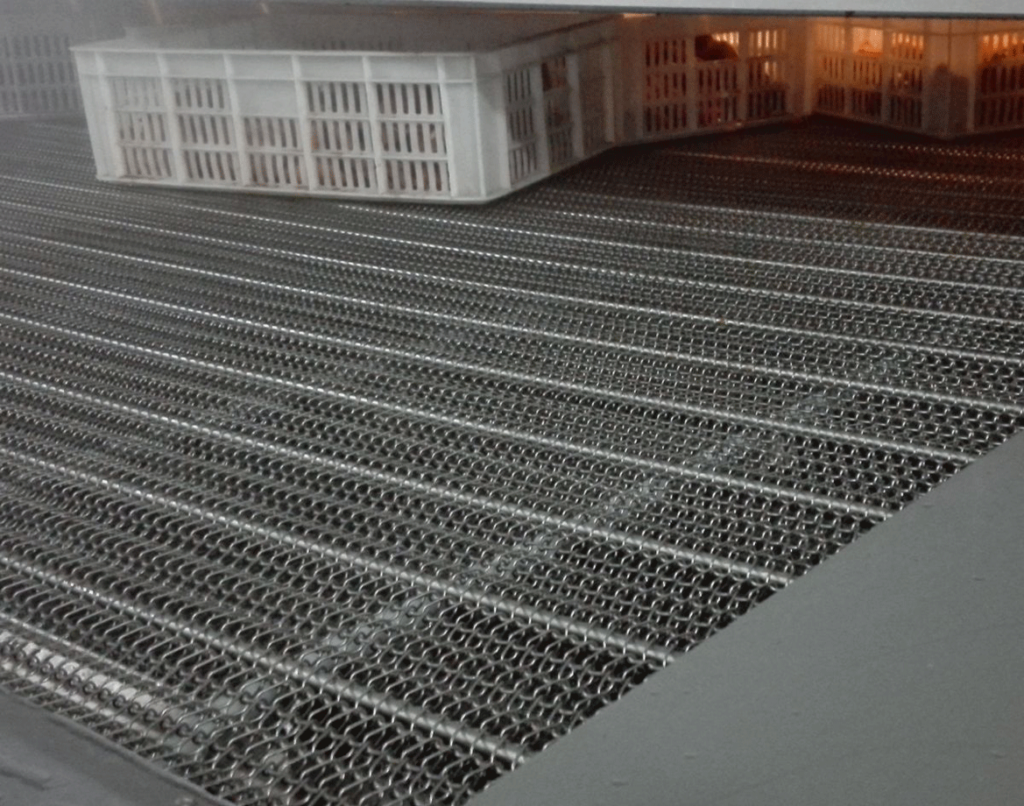

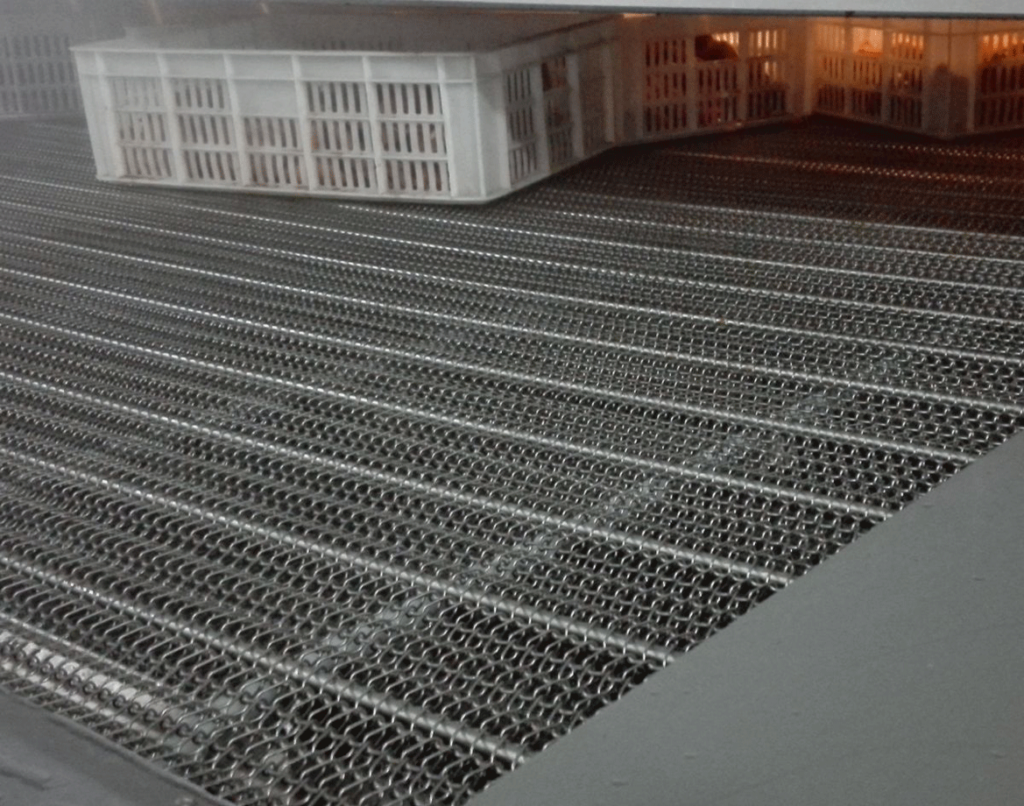

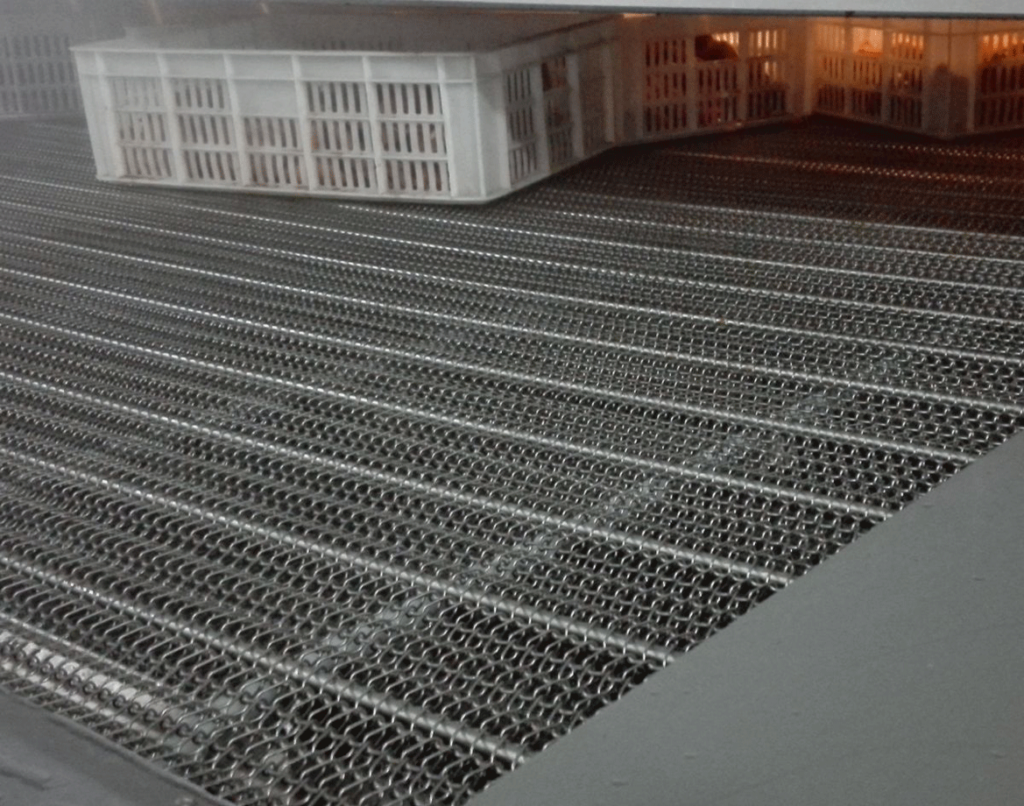

Impingement tunnel freezer library body internal unique

low-temperature airflow and air ducts make food with the

conveyor belt through the impingement tunnel freezer. the food on the lower surface of the high-speed airflow to the

opposite blowing, the surface temperature is rapidly

reduced, the time to complete the rapid freezing of food.

Capacity:

200kg/h~1000kg/h

Application Area:

Quick freezing processing of seafood, poultry, vegetables, fruits, pastas, dairy products, etc.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| ITF-200 | 200kg/h | +10℃/-18℃ | -35℃ | Continuous and adjustable | R717/R22/R404a | 3120×4400×3050 |

| ITF-500 | 500kg/h | 6000×4400×3050 | ||||

| ITF-750 | 750kg/h | 8800×4400×3050 | ||||

| ITF-1000 | 1000kg/h | 11760×4400×3050 |

Note:

1. The freezing capacity refers to fish fillets. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| BITF-500 | 500kg/h | +10℃/-18℃ | -35℃ | Continuous and adjustable | R717/R22/R404a | 10240×3420×3000 |

| BITF-750 | 750kg/h | 14950×3420×3000 | ||||

| BITF-1000 | 1000kg/h | 19660×3420×3000 |

Note:

1. The freezing capacity refers to shrimp meat. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| ITF-200 | 200kg/h | +10℃/-18℃ | -35℃ | Continuous and adjustable | R717/R22/R404a | 3120×4400×3050 |

| ITF-500 | 500kg/h | 6000×4400×3050 | ||||

| ITF-750 | 750kg/h | 8800×4400×3050 | ||||

| ITF-1000 | 1000kg/h | 11760×4400×3050 |

Note:

1. The freezing capacity refers to fish fillets. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| BITF-500 | 500kg/h | +10℃/-18℃ | -35℃ | Continuous and adjustable | R717/R22/R404a | 10240×3420×3000 |

| BITF-750 | 750kg/h | 14950×3420×3000 | ||||

| BITF-1000 | 1000kg/h | 19660×3420×3000 |

Note:

1. The freezing capacity refers to shrimp meat. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

Tunnel quick freezers come in various types, each designed for different freezing requirements and product characteristics:

Each type has its unique advantages, allowing users to choose the appropriate equipment based on product characteristics and desired freezing speed.

Impact tunnel quick freezers offer several advantages over traditional tunnel freezers, especially in terms of speed and product quality:

These advantages make impact tunnel quick freezers a preferred choice for industries looking to achieve high-quality freezing while reducing production time and maintaining energy efficiency.

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

We look forward to hearing from you!