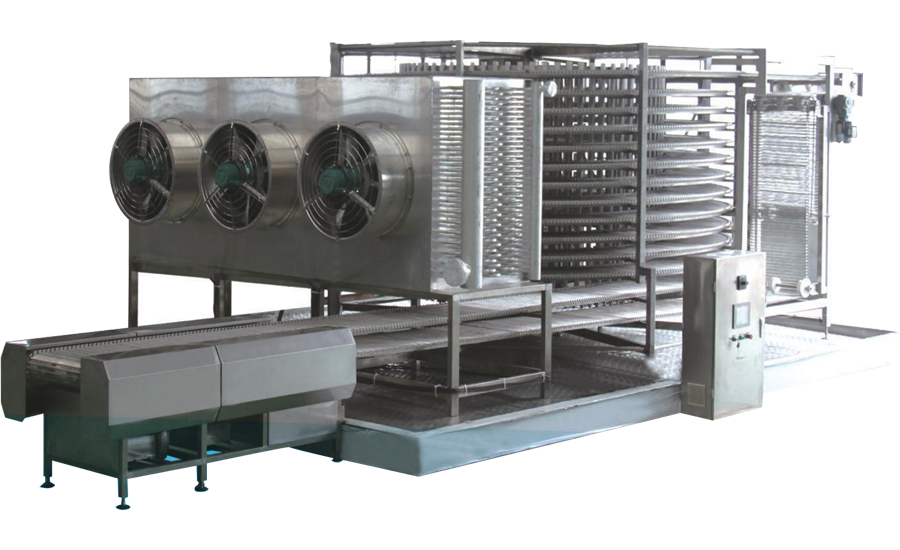

The single-drum spiral freezer is an advanced, energy-efficient rapid freezing device characterized by its compact structure, small footprint, and high freezing capacity. It is the preferred equipment in the food processing industry for freezing products with large thickness, volume, and high initial temperature, such as meat. Designed to maximize freezing efficiency within limited space, the single-drum spiral freezer is suitable for a wide range of applications and can be customized and manufactured according to customer requirements and space constraints. It serves as a high-efficiency solution for freezing large quantities of products in a small floor area.

Capacity:

200kg/h~3500kg/h

Applicationa Area:

Quick freezing processing of seafood, poultry, vegetables, pasta, dairy products, Pre-prepared dishes, etc.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| SSF-300 | 300kg/h | +25℃/-18℃ | -35℃ | 15-75min adjustable | R717/R22/R404a | 5600×4300×3000 |

| SSF-400 | 400kg/h | 5900×4700×3000 | ||||

| SSF-500 | 500kg/h | 20-100min adjustable | 6600×5300×3000 | |||

| SSF-750 | 750kg/h | 6600×5300×4000 | ||||

| SSF-1000 | 1000kg/h | 7200×6000×4000 |

Note:

1. The freezing capacity refers to fried chicken. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

| Model | Freezing capacity | Inlet/Outlet Temp. | Temp. in cabinet | Freezing time | Refrigerant | Overall dimension |

|---|---|---|---|---|---|---|

| SSF-300 | 300kg/h | +25℃/-18℃ | -35℃ | 15-75min adjustable | R717/R22/R404a | 5600×4300×3000 |

| SSF-400 | 400kg/h | 5900×4700×3000 | ||||

| SSF-500 | 500kg/h | 20-100min adjustable | 6600×5300×3000 | |||

| SSF-750 | 750kg/h | 6600×5300×4000 | ||||

| SSF-1000 | 1000kg/h | 7200×6000×4000 |

Note:

1. The freezing capacity refers to fried chicken. Refrigeration capacity is based on condensing temperature of +35℃ and evaporating temperature of -42℃.

2. The standard models listed above are for your reference. It will be designed as per specific requests.

Spiral quick freezers typically use automatic defrost systems to maintain optimal freezing efficiency. The most common methods are hot gas defrost and water defrost. Hot gas defrost involves circulating warm refrigerant gas through the evaporator coils to melt ice buildup. Water defrost uses a controlled spray of warm water to remove ice accumulation on the coils. These systems are designed to be efficient and minimize downtime, ensuring that the freezer can continue operating with minimal interruption while maintaining consistent temperature levels.

Yes, a spiral quick freezer is generally designed as a closed space to maintain controlled temperatures and ensure energy efficiency. The closed design helps to minimize heat exchange with the external environment, which is crucial for maintaining the low temperatures required for rapid freezing. This structure also helps to prevent outside contaminants from entering the freezing chamber, ensuring food safety and hygiene. The closed environment, combined with the spiral structure, ensures uniform airflow, resulting in consistent freezing of products.

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

Global Office (Sales Consulting)

Email: [email protected]

Manufacturing Plant and Warehouse

Whatsapp: +86 18115309498

We look forward to hearing from you!