In recent years, the food industry has made significant strides in meeting consumers’ demand for convenience, nutrition, and flavor. Imitation crispy shrimp balls, a novel product made primarily from fish meat, successfully recreate the taste, texture, and nutritional value of shrimp. These shrimp balls are not only delicious but also versatile, making them suitable for soups, frying, hot pot, and various other cooking methods. This article provides a detailed overview of the production technology behind imitation crispy shrimp balls and emphasizes the critical role that modern freezing equipment plays in ensuring product quality.

Selection of Raw Materials and Equipment

The key to producing high-quality imitation crispy shrimp balls lies in selecting fresh or frozen surimi (fish paste). The surimi should have good elasticity, a bright white color, and excellent freshness to achieve the best product outcome. The primary ingredients include surimi, shrimp flavoring, meat improvers, and starch, which together give the shrimp balls their unique taste and texture.

The essential equipment used in the production process includes meat grinders, high-speed meatball machines, and automatic meatball formers. While small-scale production can be done without a meatball former, the meat grinder and high-speed meatball machine are crucial for ensuring product quality. These machines not only affect the efficiency of surimi processing but also directly influence the final product’s texture and flavor.

Production Process of Imitation Crispy Shrimp Balls

The production of imitation crispy shrimp balls involves several critical steps:

- Surimi Preparation

Surimi can be made from freshly prepared fish paste or thawed frozen surimi. Select fish with good meat quality and thickness, remove the bones and skin, and grind the fish using a meat grinder with a 2mm screen to obtain surimi. For large-scale production, a fine filter can be used for surimi processing. The ground surimi should be frozen for 3-4 hours or quick-frozen for 30 minutes before proceeding to the next production step. If using frozen surimi, it must be thawed first. - Chopping and Blending

The ground surimi is chopped and blended using a high-speed meatball machine to break down the fish tissue, facilitating the dissolution of salt-soluble proteins during the blending process. Temperature control is crucial during chopping, and ice should be placed in the meatball machine’s cooling tank to maintain the appropriate temperature. The entire chopping process is divided into three stages: empty blending, salt blending, and flavor blending.

- Empty Blending: The chopped surimi is placed in the meatball machine, and meat improvers are added. The mixture is blended for 20-30 seconds to further break down the fish tissue.

- Salt Blending: Add 2%-3% salt and continue blending for another 20-30 seconds. At this stage, the surimi gradually becomes sticky as salt-soluble proteins are released.

- Flavor Blending: Finally, add sugar, starch, monosodium glutamate, and other seasonings, and blend for 20 seconds. The mixture is then transferred to a mixer for final mixing.

3. Forming the Balls

There are two methods for forming the shrimp balls:

- Manual Forming: The blended surimi is manually shaped into balls and placed in warm water (50-60°C) for 10-15 minutes to set.

- Machine Forming: The surimi mixture is placed in an automatic meatball former, which shapes the balls according to the selected mold size (small, medium, or large). The formed balls are then placed in warm water to set.

4. Cooking and Cooling

The formed shrimp balls are cooked in 90°C hot water for 15-20 minutes, then removed and cooled with cold water. After cooling, the balls are placed in a cold storage unit to chill before packaging.

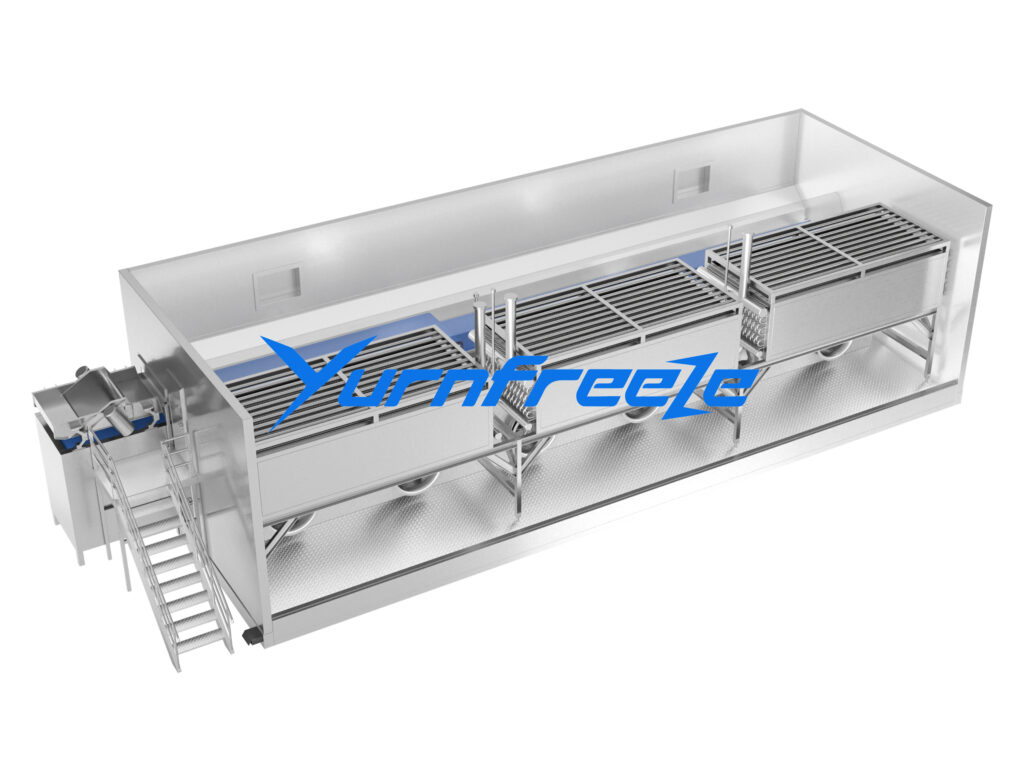

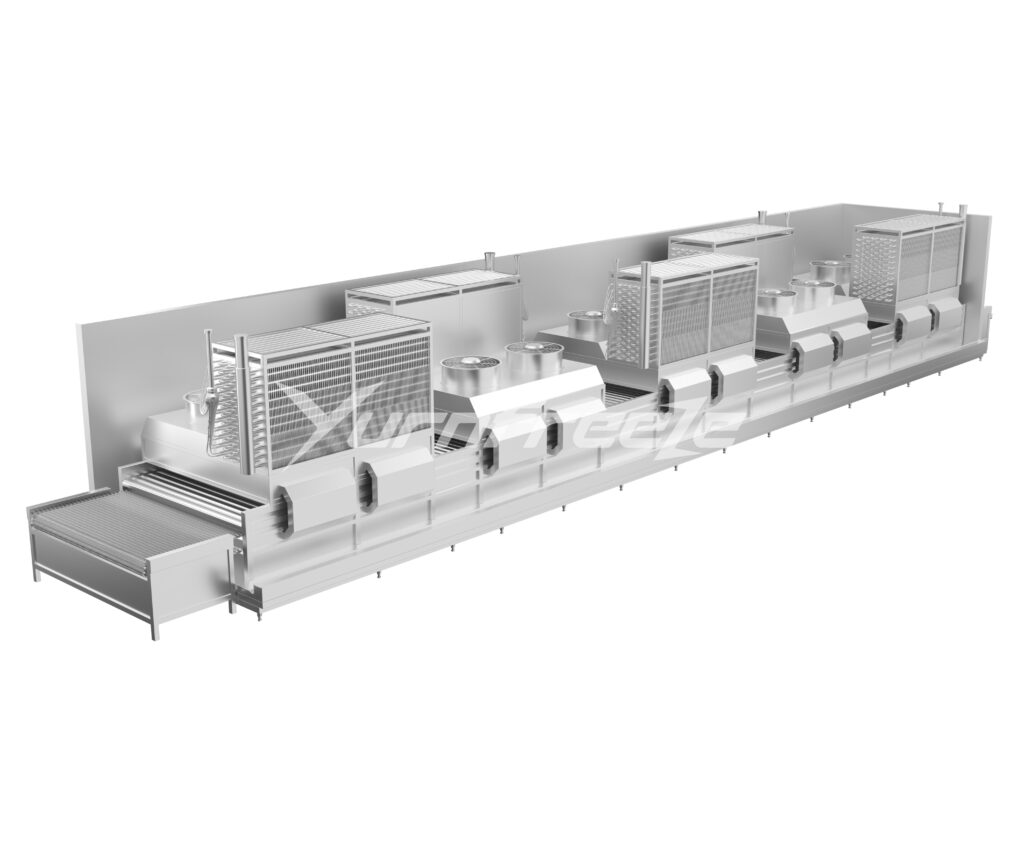

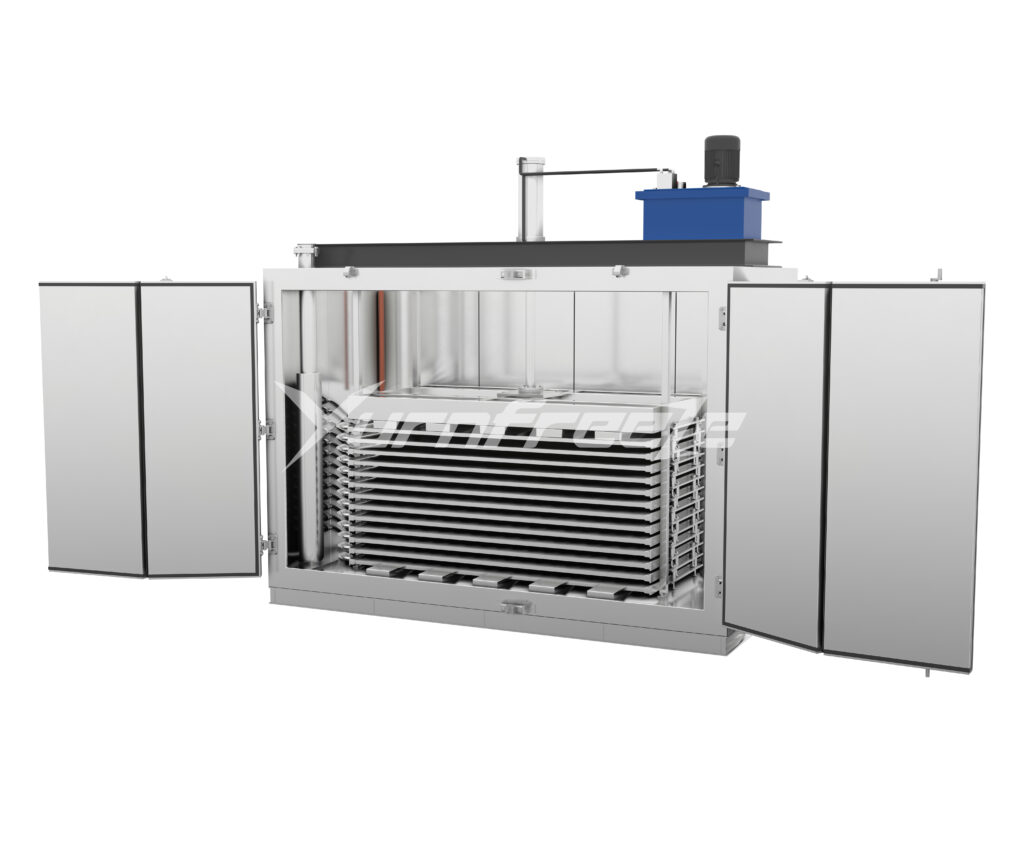

The Crucial Role of Freezing Equipment

Freezing equipment plays a vital role in the production of imitation crispy shrimp balls. Advanced freezing technology helps lock in the nutritional content of the surimi while ensuring the product’s texture and freshness. The quick freezing process prevents the formation of large ice crystals inside the shrimp balls, maintaining their delicate texture and ensuring they have the same elasticity and crispiness as real shrimp meat.

Moreover, efficient freezing equipment enhances production efficiency, meeting the demands of large-scale production and ensuring product consistency and quality. In the food processing industry, freezing equipment is essential for extending the product’s shelf life, reducing costs, and delivering high-quality products to consumers.

Conclusion and Collaboration Opportunity

The production of imitation crispy shrimp balls showcases the innovative capabilities of the food processing industry. By combining traditional techniques with modern technology, this product excels in meeting consumers’ needs for convenience, nutrition, and flavor. However, this success is closely tied to the support of high-quality freezing equipment.

Our company specializes in providing advanced freezing solutions tailored to the needs of food processing enterprises. Whether you are producing imitation crispy shrimp balls or other frozen food products, our equipment can help you improve production efficiency, maintain product quality, and extend shelf life. With extensive experience in the industry, we are committed to understanding and addressing the specific needs of our clients.

If you are looking to improve your production processes or explore how to better maintain the high quality of your products, we invite you to contact us. Our professional team is ready to provide customized solutions and support you every step of the way. We look forward to collaborating with you to advance the food processing industry together.