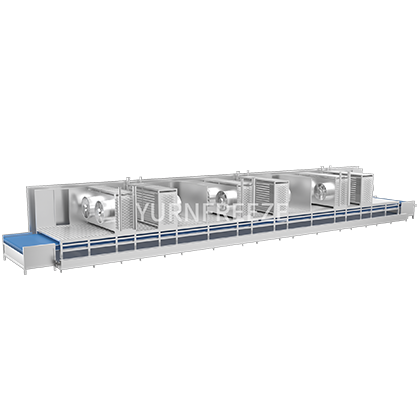

A tunnel freezer is a widely used low-temperature freezing system, especially suitable for the food industry’s need for efficient freezing. Its core design is a low-temperature tunnel that can quickly cool and freeze food through precise temperature and airflow control. The product enters the tunnel in a hot state or at normal temperature and is output frozen from the other end, significantly improving production efficiency and product quality.

How tunnel freezer works

Most tunnel freezers use liquid nitrogen (-196°C) or carbon dioxide (-56.6°C) as the refrigerant. The key components of the cooling process include:

Thermal insulation shell: maintains the low-temperature environment in the tunnel and ensures product freezing efficiency.

Conveyor Belt: Smoothly transports food through the freezing tunnel.

Injection system: Precisely inject liquid refrigerant into the refrigeration system to provide the necessary low-temperature environment.

Ventilation system: Evenly distributes cold air to ensure consistent product surface temperature.

Exhaust system: eliminate excess gas and optimize system performance.

Diverse designs of tunnel freezers

Although most tunnel freezers have a similar basic structure, their design and configuration can vary significantly depending on specific application needs. Here are the main design types and their characteristics:

1. Refrigerant selection: liquid nitrogen vs. carbon dioxide

Liquid nitrogen: faster cooling, safer operation, generally suitable for scenarios that require rapid freezing, and has lower maintenance costs.

Carbon dioxide Inhibits bacterial growth under certain conditions and positively impacts the color retention of certain meat products. However, these advantages require that the product be maintained in a carbon dioxide environment after freezing.

2. Conveyor belt configuration

Single conveyor belt design: suitable for rapid freezing of a single product to prevent dehydration.

Multi-conveyor design: Supports freezing of multiple products at the same time and allows parameters (such as temperature and speed) to be set independently for each conveyor belt.

Staggered conveyor design: specially developed for IQF (Individually Quick Frozen) products to prevent product sticking and ensure uniform freezing on all surfaces.

Special material conveyor belts: such as smooth stainless steel conveyor belts, specially designed for fragile products, which can effectively prevent products from being damaged during the transportation process.

3. The flow pattern of cryogenic liquids

Linear freezing: The low-temperature airflow moves along the direction of product flow, and the gas is injected from the tunnel entrance and discharged from the exit.

Counterflow freezing: low-temperature gas is injected at the end of the tunnel and flows countercurrently to the entrance. The counter-flow design can extend the time the product is exposed to cold gas and further improve freezing efficiency.

Diverse applications of tunnel freezer

Tunnel freezers can be widely used in the freezing processing of meat, seafood, pasta, fruits, and other foods, and are an important tool for food manufacturers to improve productivity and product quality.

The core advantages of tunnel freezer

Tunnel freezers are favored by food manufacturers because of their efficiency and reliability. Their advantages are mainly reflected in the following aspects:

Compact design

Tunnel freezers typically have a smaller footprint than traditional refrigeration systems. Because the extremely low freezing temperatures quickly reduce product temperature, the required conveyor belt length is significantly reduced, making the equipment even more space-saving.

Quick freezing to improve efficiency

The tunnel freezer can cool food with extremely high efficiency and quickly complete the freezing process to avoid delays in the production process due to cooling. Improvements in production efficiency directly lead to higher production capacity, helping companies achieve additional sales growth.

Preserve food quality

The use of rapid freezing technology can effectively protect the cell structure of food and prevent moisture loss, thereby maximizing the retention of nutrients and vitamins. This is especially important for most foods, ensuring that their texture, taste, and nutrition remain at their best after freezing. However, for certain foods, a slower freezing process may be more suitable, in which case controlled rate freezing equipment may be used.

Cryogenic infrastructure for tunnel freezers

The cryogenic system design of each tunnel freezer is different, and its performance depends heavily on the supporting cryogenic infrastructure.

1. Professional connection and installation

Through years of practical experience, our professional team can design and install customized cryogenic systems for various tunnel freezers. The team ensures that the freezer is properly connected to the Dewar flasks that store cryogenic liquids, such as liquid nitrogen or carbon dioxide, and is operating at maximum efficiency.

2. Component configuration

The cryogenic infrastructure of a tunnel freezer typically consists of the following core components:

Vacuum-insulated transmission pipeline: Reduce heat loss during the transmission process of refrigerant to ensure efficient use.

High-performance connectors: Ensure connection tightness, prevent leaks, and improve system stability.

Quality-enhancing components: such as fluid control valves and pressure regulators, ensure the refrigerant always enters the freezer in optimal condition.

Through optimized design, these infrastructures ensure that cryogenic liquids are delivered to the tunnel freezer with the highest quality, providing stable support for the freezing process.

The tunnel freezer is not only a powerful tool for efficiently freezing food, but its supporting low-temperature infrastructure is also critical. We are always committed to providing customers with comprehensive solutions to help you maximize production efficiency. If you have any questions about the configuration of your tunnel freezer or cryogenic system, please feel free to contact us!