1. Cleaning & lifting Shrimp

Shrimp is the raw material, and all the raw materials are live. The live shrimp is directly pulled from the shrimp pond to the factory through some small trucks and then weighed. After weighing, the shrimp is lifted and cleaned. Put it in the washing machine for cleaning, usually once. Because boiled shrimp must be live shrimp, the cooked shrimp will look good, and if it is not live shrimp, if the cooking time is a little longer, the shrimp head of the cooked shrimp will be black. Therefore, when sorting, the workers pick the shrimp because they want to pick out the blackhead shrimp, otherwise, the quality will be affected. The selection of blackhead shrimp is all manual operation.

2. Cooking shrimp

Starting from the production line, boiled shrimp is purchased from the previous raw materials and weighed, then goes to the elevator and washing machine, and then enters the shrimp cooking machine. There are two types of boiled shrimp, one is steamed shrimp and the other is boiled shrimp. Steamed shrimp is steamed, that is, the shrimp is placed on the mesh belt, like a tunnel machine, and then the steam from the steam machine is used to steam the shrimp; the other is that the shrimp passes through the water, similar to the lifting machine and glazing machine. The steam is passed into the water, which boils the water and cooks the shrimp.

Sometimes the customer wants to steam and sometimes the customer wants to cook. There may be some differences in color and shape. It may be that the shape of the steamed shrimp is better. However, steaming shrimp is wasteful, consumes a lot of steam, and has low efficiency, while cooking shrimp is more efficient. Cooking shrimp can cook 2000~3000kg for an hour at a time, but steaming shrimp may only be 1500kg~2000kg for an hour, and the speed of steaming shrimp may be slower.

3. Cooling shrimp

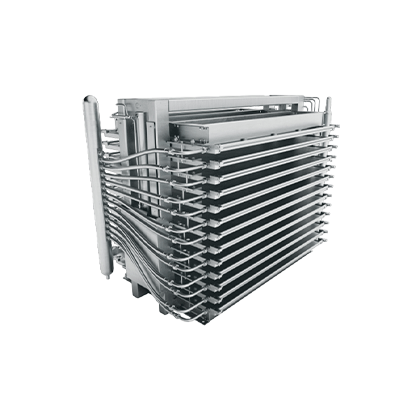

After cooking, the shrimp need to be cooled. They cannot be directly put into the quick freezer or grading machine directly, because they are too hot. It is generally divided into two cooling processes. The first cooling is with normal temperature water. Now instead of using tap water, factory will use relatively high-grade pure water, which is similar to the purified water we usually have at home. It has a relatively large purifier, and the purifier is separated calcium and magnesium ions and other impurities.

The second step is to use ice water for refrigeration. This ice water is pumped by a compressor, and there is a drain pipe on the side, similar to the drain pipe on the side of the glazing machine. The temperature of the ice water is relatively low. Although it generally does not reach 0 degrees, it is generally around a few degrees above zero, about five or six degrees. The first step does not use ice water because the temperature of shrimp in the first step is very high, it is wasteful to use ice water.

4. Grading shrimp

After cooling twice, it is necessary to sort the size. There are about six types of general grading machines. There are three conveyor belts on one side of the grading machine, two on the other side, and the one that falls directly from the front is the bigger shrimp. No matter how big it falls out, it is one specification, and the others can be divided into five specifications, which are more refined.

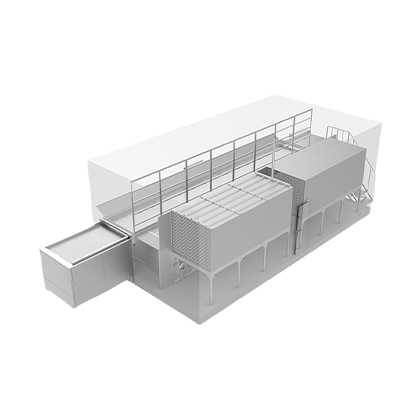

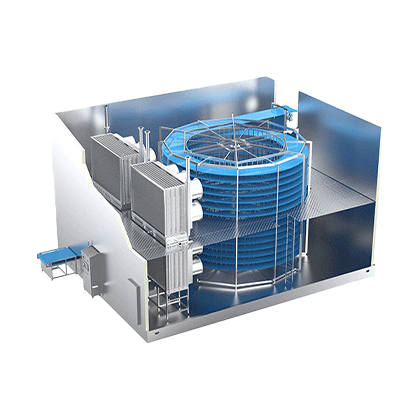

5. Quick freezing shrimp

After being sorted by the grading machine, it has to go through quick freezing, and the front is either a spiral freezer or a tunnel freezer. There is still a link between grading and quick-freezing. Sometimes customers will put the shrimp in a large bucket (water-retaining agent) to soak for a while. And the function is to increase the weight. Ice needs to be added to the bucket, and the temperature should not be high.

After soaking, customers generally add a lifting machine to lift the buckets to the quick-freezing production line. After the shrimp is lifted up, a vibrating distribution machine may be added, and then a conveyor line will be added behind. The purpose of adding the conveyor line is to allow more workers to stand on both sides to pick black-headed shrimps or those with heads off or soft shells. Then shrimp enters the spiral freezer or tunnel freezer for quick freezing. After the quick freezing, there will go through glazing machine and hardening machine, and then packed. Generally, in China, farmers’ markets or supermarkets are packed in a large cardboard box, about 10kg~20kg per box.